Peening media

High-performance solutions for shot peening and surface enhancement!

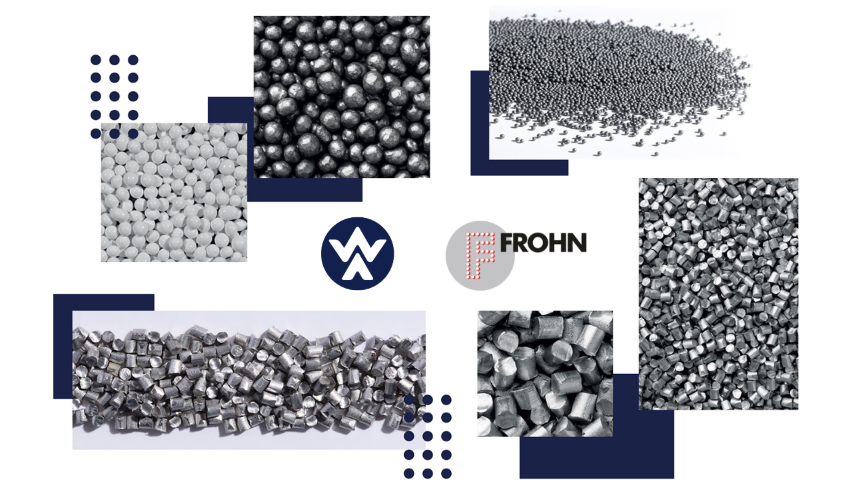

Frohn & W Abrasives

Winoa offers a complete range of high-precision peening media designed to meet the most demanding specifications in aerospace, automotive, energy, and general manufacturing. Through our Frohn™ brand—Winoa’s dedicated cut wire peening shot brand — and W Abrasives, cast steel peening media, we deliver industry-leading solutions to enhance surface integrity & fatigue resistance with cut wire, AMS cast steel shot, stainless steel shot, aluminum media, high-durability HD Cut Wire and Ultra Fine Shot.

The most common types of media used in shot peening are available

Explore our media offerings

Discover our selection of shot peening media, from the durability of high carbon steel shot to the fine finishing touch of glass beads.

Trusted Performance, Global Support

Why choose Frohn

Frohn™ is Winoa’s dedicated brand for shot peening applications. Known for outstanding dimensional control, surface finish, and durability, Frohn products are manufactured in Germany, the USA, and China to serve local markets with global consistency.

As part of the Winoa Group, Frohn benefits from advanced R&D resources, continuous innovation, and technical synergies with W Abrasives’ high-spec products such as AMS-compliant media, as well as Winoa’s service expertise through diagnostics, training, and process optimization.

Precision media for demanding applications

Where performance matter

Frohn’s & W Abrasives shot peening media are engineered for use in industries where surface integrity, fatigue resistance, and dimensional precision are mission-critical. Whether enhancing spring life in suspension systems or preparing turbine blades for high-stress environments, Winoa offers the right solution—with compliance to AMS 2431, SAE J441, VDFI 8001, and more.

Media Selector Guide

Technical Comparison

| Media Type | Typical available Hardness (HRC) | Service Life | Recommended Applications | Additional Insights |

| Steel Cut-Wire | 45–62 | High | Springs, Gears, General Manufacturing | Cost-effective for high-throughput environments |

| HD Cut-Wire | 45–62 | Very-High+30% vs Steel CW | High-volume Automotive, Foundry, Aerospace | Reduces downtime with lower breakage and dust |

| AMS Cast Steel Shot | 45–62 | High | Aerospace Components, Peen-Forming | Fully AMS 2431/1 or /2 compliant, ideal for certifications |

| Stainless Cut-Wire | 40–55 | High | Petrochemical, Medical, Corrosive Zones | Combines precision with corrosion resistance |

| Stelux (Cast Stainless) | 40–55 | Medium | Offshore, Medical, Food Equipment | Non-contaminating stainless shot with excellent recyclability |

| SAE Cast Steel Shot | 41–54 | Medium | Automotive Suspension, Rail, General Parts | Widely used, cost-balanced, and available globally |

| Ultra-Fine Shot (UFS) | >60 HRc / >700 Hv | Moderate | Mold Tools, Micro Gears, Dual Peening | Enables low-intensity peening with fine media control |

Service Life Categories

To help guide your selection, we classify media service life into five tiers:

- Very High: Maximum recyclability, >3,000 cycles under standard conditions

- High: Long-lasting in tough environments, typically 2,000–3,000 cycles

- Medium: Balanced cost/life ratio, ~1,000–2,000 cycles

- Standard: General-purpose, 500–1,000 cycles

- Moderate: Precision control over life span, <500 cycles for specific applications

Global Standards. Certified Performance.

Certifications & Technical Support

All Frohn and W Abrasives shot peening media are manufactured under strict quality control, with full traceability and compliance to international specifications including:

- AMS 2431 / SAE J441 / VDFI 8001

- ISO-certified production facilities in Europe, North America, and Asia

Customers also benefit from Winoa’s extensive support capabilities:

- Technical audits and diagnostics

- In-house and on-site training

- Media selection, conditioning, and optimization

- Winoa’s W Care services and access to local support experts

What’s new in Shot Peening Media

Discover some news

Resources & Contact Options

Get in Touch

Download Shot Peening Brochure Browse Specifications & Certificates