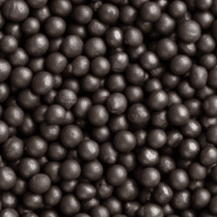

Steel Shot abrasive

W Abrasives™ reliable, quality, high carbon steel shot, that exceeds the topmost manufacturing standards

Our steel shot, manufactured under strict conditions and a unique tempering process, allows you to obtain a high carbon cast abrasive shot with optimal resilience, low chlorides & conductivity and high fatigue resistance. Used mainly in shot blasting applications, from desanding in foundries to descaling in steel mills, our HC steel shot will meet your most demanding needs.

Steel shot users benefits

Steel shot users benefits

3 KEY FEATURES

Enhance your surface preparation capabilities with our steel shot abrasive.

100% Recyclable

Choose our environmentally friendly steel shot blasting abrasive, crafted from high carbon steel to ensure enduring efficiency. Embrace sustainability without sacrificing performance.

Air quenched

Explore enduring resilience with our thermally toughened steel shot. Through a thermal process, our high carbon shot optimizes cleaning results, delivering long-lasting strength for your applications.

Globally Available

Depend on our steel shot for universal availability, ensuring a steadfast and reliable source for all your cross-continental surface preparation requirements.

Performances of steel shot

Performances of steel shot

Balancing hardness and efficiency

48 HRC Hardness – for optimal performances

With a hardness of 48 HRC, W Abrasives’ shot strike the right balance between consumption and efficiency: an amount of impact energy large enough to do the cleaning job desired, while being just soft enough to reduce the wear of the machine and media consumption.

Consistent surface finish

Formulated with a narrow hardness range, which equates for your production process a more consistent, stable and reliable cleaning results.

Reduced risk of coating failure

With our chloride and salt levels below 50 μS/cm, you are sure to reduce the possibility of surface contamination due to your abrasive, ensuring increased longevity of the coatings

SP version for High impact and Peening

Specific hardness are available for some hard to clean and peening applications. Typical targetted hardness are: 54 RHC and 58 RHC.

Markets and applications

Markets and applications

Steel Shot's Impact

Discover the versatile applications of steel shot in markets such as foundries, forges, steel mills, and the automotive industry.

Foundries

Forges

Steel mills

Automotive

Specifications

Specifications

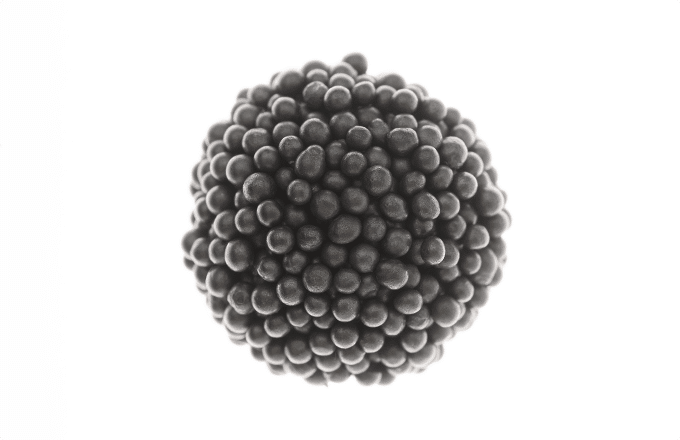

Find here the standard specifications and properties of our carbon steel shot, including hardness, shape, size, micro-structure, toughness, etc. We manufacture 2 standard specifications, either SAE (mainly used in Americas and Asia), or WAE (mainly used in Europe).

| Chemical analysis | According to standard SAE J827 %C 0,8-1,2 %Si 0,4-1,2 %S < 0,05 %P < 0,05%Mn 0,35-1,20 : S070 and S110 %Mn 0,50-1,20 : S170 %Mn 0,60-1,20 : S230 and above |

| Sieve analysis | According to standard SAE J 444 |

| Hardness | 40-51 HRC (390 – 530 HV) *other hardness available upon request for Peening applications (54 HRC and 58 HRC as standard) |

| Standard deviation | On 10 measurements taken halfway across the particle radius. Arithmetic means of absolute values of deviations: < 3 HRC |

| Standard deviation | ± 3 Rc or ± 40 HV |

| Microstructure x500 | Tempered martensite with 15% residual austenite |

| Minimum density measured by alcohol displacement | > 7.0 g/cm |

| Conductivity | < 30 µS/cm |

If your needs require other specifications, please contact our teams here

Size distribution

Size distribution

| Steel shot

Product |

Sieve opening in mm (values given in cumulated weight %) | ||||||||||||||||

| 2,8 | 2,36 | 2 | 1,7 | 1,4 | 1,18 | 1 | 0,85 | 0,71 | 0,6 | 0,5 | 0,42 | 0,35 | 0,3 | 0,18 | 0,12 | 0,07 | |

| S780 | AP | 85% min | 97% min | ||||||||||||||

| S660 | AP | 85% min | 97% min | ||||||||||||||

| S550 | AP | 85% min | 97% min | ||||||||||||||

| S460 | AP | 5% max | 85% min | 96% min | |||||||||||||

| S390 | AP | 5% max | 85% min | 96% min | |||||||||||||

| S330 | AP | 5% max | 85% min | 96% min | |||||||||||||

| S280 | AP | 5% max | 85% min | 96% min | |||||||||||||

| S230 | AP | 10% max | 85% min | 97% min | |||||||||||||

| S170 | AP | 10% max | 85% min | 97% min | |||||||||||||

| S110 | AP | 10% max | 80% min | 90% min | |||||||||||||

| S070 | AP | 10% max | 80% min | 90% min | |||||||||||||

| Screen Number | 7 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 80 | 120 | 200 |

| Screen Size (mm) |

2,8 | 2,36 | 2 | 1,7 | 1,4 | 1,18 | 1 | 0,85 | 0,71 | 0,6 | 0,5 | 0,42 | 0,35 | 0,3 | 0,18 | 0,12 | 0,07 |

| Screen Size (inches) |

0,111 | 0,0937 | 0,0787 | 0,0661 | 0,0555 | 0,0469 | 0,0394 | 0,0331 | 0,0278 | 0,0234 | 0,0197 | 0,0165 | 0,0139 | 0,0117 | 0,007 | 0,0049 | 0,0029 |

Cumulative Size Distribution (%)

Document for informational puspose only. Not contractual.

Contact your local representative for latest version of the technical data sheets.

|

Product |

Sieve opening in mm (values given in cumulated weight %) | ||||||||||||||||

| 2,8 | 2,36 | 2 | 1,7 | 1,4 | 1,18 | 1 | 0,85 | 0,71 | 0,6 | 0,5 | 0,42 | 0,35 | 0,3 | 0,18 | 0,12 | 0,07 | |

| W S780 | 0 | >90 | >97 | ||||||||||||||

| W S660 | 0 | <20 | >97 | ||||||||||||||

| W S550 | 0 | <30 | >90 | >97 | |||||||||||||

| W S460 | 0 | <30 | >90 | >97 | |||||||||||||

| W S390 | 0 | <20 | >85 | >97 | |||||||||||||

| W S330 | 0 | <10 | >85 | >97 | |||||||||||||

| W S280 | 0 | <30 | >90 | >97 | |||||||||||||

| W S230 | 0 | <30 | >90 | >97 | |||||||||||||

| W S170 | 0 | <30 | >90 | >97 | |||||||||||||

| W S110 | 0 | <20 | >90 | >97 | |||||||||||||

| W S070 | 0 | <5 | >90 | >97 | |||||||||||||

| Screen Number | 7 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 80 | 120 | 200 |

| Screen Size (mm) |

2,8 | 2,36 | 2 | 1,7 | 1,4 | 1,18 | 1 | 0,85 | 0,71 | 0,6 | 0,5 | 0,42 | 0,35 | 0,3 | 0,18 | 0,12 | 0,07 |

| Screen Size (inches) |

0,111 | 0,0937 | 0,0787 | 0,0661 | 0,0555 | 0,0469 | 0,0394 | 0,0331 | 0,0278 | 0,0234 | 0,0197 | 0,0165 | 0,0139 | 0,0117 | 0,007 | 0,0049 | 0,0029 |

Cumulative Size Distribution (%)

Document for informational puspose only. Not contractual.

Contact your local representative for latest version of the technical data sheets.

W Abrasives steel abrasives sizes and general applications

W Abrasives steel abrasives sizes and general applications

The above chart lists the abrasive sizes most commonly used in blasting operations – the encircled dots to the left of the SAE number represent the approximate shape and size of actual abrasive pellets. The round W Abrasives Steel Shot is heat treated and drawn to a hardness of 40 to 51 Rockwell “C”. W Abrasives angular products are available in various degrees of hardness. (Based on results obtained with a 191/2” dia. w/a at 2250 R.P.M.). * Not often used

Frequently Asked Questions (FAQ) about steel shot

Frequently Asked Questions (FAQ) about steel shot

Key inquiries in steel shot abrasives

Steel shot blasting is a surface preparation process using high carbon steel shot to clean, descale, or strengthen surfaces. It is widely employed in industries such as foundries, forges, steel mills, and automotive for its efficiency.

Steel shot is commonly used in shot blasting applications for desanding in foundries, descaling in steel mills, and other surface preparation needs. Its high carbon cast composition ensures optimal resilience and performance.

Shot blasting is generally straightforward and its performance can be easily optimized with the correct equipment, the right expertise, and the use of high-quality abrasives such as W Abrasives steel shot. However, the simplicity of the process also varies based on the specific application, the complexity of the workpieces and the desired finish.

Sandblasting uses typically sand particles and other non-metallic abrasive for surface cleaning or preparation, while shot blasting employs metallic shots (high carbon, low carbon, cut wire shot, and more) to achieve more efficient and durable outcomes.

Steel shot offers consistent surface finish due to its narrow hardness range, providing more stable and reliable cleaning results for your production process.