HPG, High-Productivity Grit by W Abrasives™

High-Productivity Grit designed for desanding operations

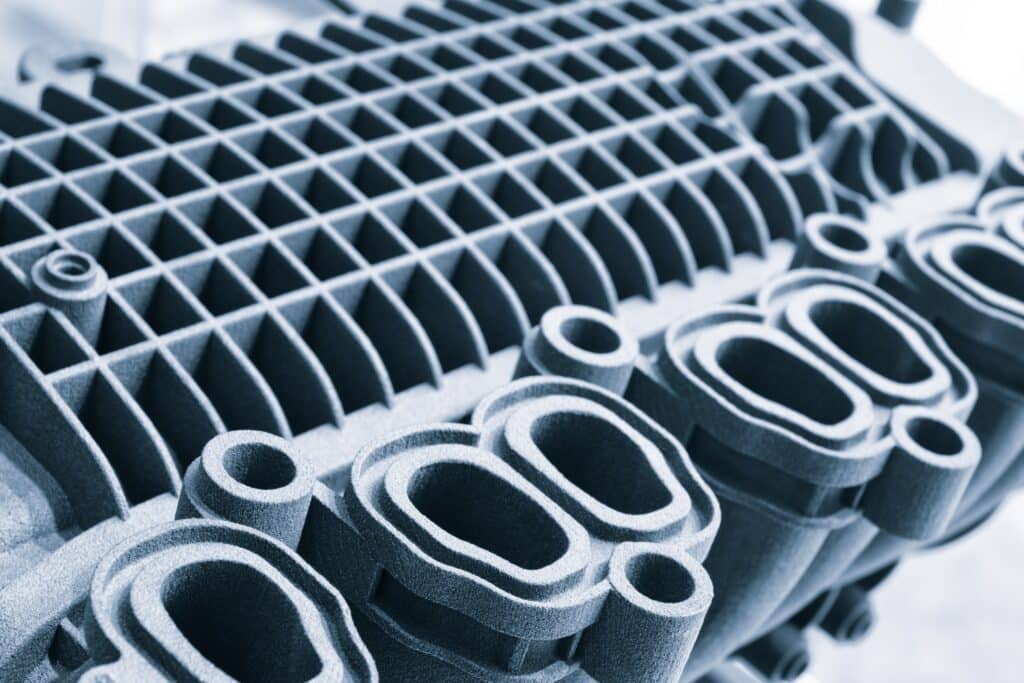

HPG, our Premium cast steel media for foundries, is an angular abrasive specifically designed to improve the cleaning and descaling performance of shot blasting. It works faster, makes cleaner parts and lasts longer than typical cast steel shot used in foundries. Its ability to remove and clean sands, resins or steel scale is unmatched.

Users benefits

Users benefits

Cleaning operations

Homogeneous and stable operating mix

Long life

Elliptic grain shape

Performances

Performances

Markets & Applications

Markets & Applications

Desanding & descaling

Specifications

Specifications

| Product name | HPG 2 | HPG 4 | HPG 4+ | HPG 6 | HPG 8 |

| Nominal size (Sieve #) |

1,70 mm (#12) | 1,40 mm (#14) | 1,18 mm (#16) | 1,18 mm (#16) | 1,00 mm (#18) |

| Hardness | 48 – 52 HRC | ||||

| Density | Absolute ≥ 7 g/cm3 Apparent ≥ 4 g/cm3 | ||||

| Chemical composition | Carbon: 0.80 to 1.20% Manganese: 0.6 to 1.20% Silicon: 0.40% min Phosphorus : 0.05% max Sulfur : 0.05% max | ||||

| General shape | Angular | ||||

| Packaging | BOXED BAGS : 1000 kg (2,205 lb), 40 bags of 25 kg (55 lb) per pallet

BIG BAG : 1000 kg (2,205 lb) DRUM : 771 kg (1700 lb) |

||||

Other sizes and specifications available after evaluation. Please contact us for details.

Find there our success story of HPG

Find there our success story of HPG

Resources & downloads

Resources & downloads

HPG brochure

You may also like

You may also like

Premium Steel Media

This exclusive combination of a Premium Product ensuring better performance than standard products, and a Premium Service to guarantee the optimum use of these products in order to obtain better results in terms of quality and cost, is a pillar of the W Abrasives philosophy.