Cut Wire

What is cut wire shot ?

Commitment to Excellence

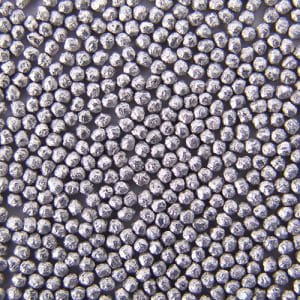

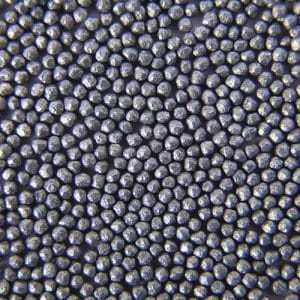

Cut wire shot pellets are produced by cutting a metallic wire into lengths equal to the diameter of the wire. For shot peening operations, the cut wire pellets are rounded (or conditioned) to eliminate sharp edges that could damage the shot peened parts.

Available in 2 grades for the steel media, regular or HD, our High Durability (HD) steel cut wire is a specially heat-treated peening shot media that will help you save cost with its extended life and quality manufacturing, while ensuring the best performance from your peening process.

What characterizes our cut wire shot

Market-Leading Performance

What all our customers are striving for, all over the world, regardless of their sector of activity? To have service, tools and technologies and cut wire media that meet the highest requirements, in which they can have complete confidence.

As the market reference in surface preparation shot media, W Abrasives guarantees its “cut wire” products a high level of performance in terms of :

- Durability & product lifespan

- Quality with a homogeneous microstructure

- Consistency in hardness & particle size

Our cut wire products are characterized by 4 main properties:

- Size From 0.25 to 3 mm

- Conditioning level from G1, G2 and G3

- Hardness from 300 to 800 Hv

- Metallurgy: available in Carbon steel, Alloyed steel, Stainless Steel, Zinc, Aluminum.

Your benefits using W Abrasives' HD cut wire shot

Elevate Your Shot-Peening Operations

The highlights of our HD steel cut wire range lie in 3 main points:

Cost-efficience

Thanks to its unique heat-treatment process, High-Durability Cut Wire shows an extended life of

+30% compared to conventional cut wire shot, leading to more cost-efficient shot-peening operations.

Ecofriendly

+30% life means reduced wastes output for your machine, making your shot-peening process more ecofriendly than ever!

Quality

Top notch quality product, made in Japan by Toyo Seiko company. It is able to deliver a stable peening effect thanks to its highly consistent particles size and hardness.

Explore our comprehensive Cut wire range

Cut wire shot

Discover abrasive solutions within our comprehensive cut wire range. Uncover the unique benefits of our Cut Wire, HD Cut Wire, aluminum or Zinc cut wire for enhanced performance in various industrial applications.

Winoa's cut wire shot for different markets & applications

Shot peening at its best

While the road transportation segment represents more than 80% of the cut wire market, our products are versatile and applicable in various industries, including Automotive, Aerospace, Medical, and Oil & Gas.

Automotive

Aerospace

Medical

Oil & Gas

Adhering to industry standards

Keeping pace with evolving market needs

Meeting key standards

The market of cut wire shot evolves regularly, both to accompany the new needs of our customers, and to meet the specific requirements in terms of peening shot.

We find 5 main standards of cut wire that we produce to:

Automotive applications:

- VDFI 8001 issued by German Spring Association : Peening media : cut wire shots

- SAE J441 issued by SAE International : cut wire shot for vehicle surface

Aerospace applications:

- 3 for aerospace applications

- AMS 2431/3 (AWCR) : conditioned carbon steel cut wire shot – Regular hardness

- AMS 2431/8 (AWCH) : conditioned carbon steel cut wire shot – High hardness

- AMS 2431/4 (AWS) : conditioned stainless steel cut wire shot

- All issued by SAE International

Your industrial challenges, our solutions

But some customers use their own standard, because of the specificities of their production, or the niche markets they address. The scope of application is not the same for each standard. To provide the best performance and reliability, work with our teams to precise which standard is needed and should be applied.

Whatever your constraints, you will find at WINOA a precise answer to your industrial challenges.

Frequently Asked Questions (FAQ) about cut wire

Exploring common inquiries on cut wire and expert insights

Steel Cut Wire Shot is primarily used in shot peening operations, delivering superior performance across industries such as Automotive, Oil & Gas, Aerospace, and Medical. In addition to peening, it can also be employed in cleaning and descaling operations.

Other metallic cut wire types, such as zinc and aluminum, are commonly used in various applications like descaling aluminum die casting and non-sparking tasks, making them versatile solutions for specific industrial needs.

Cut wire shot pellets are produced by cutting a metallic wire into lengths equal to the wire diameter. For shot peening, the pellets are rounded to eliminate sharp edges (conditioned), ensuring safe and effective use.

Cut wire shot typically comes in sizes ranging from 0.3 to 2.0 mm, as cut or conditioning levels G1, G2, and G3, offering versatility for different applications.

High-Durability Cut Wire, with its unique heat-treatment process, exhibits a +30% extended life compared to conventional steel cut wire, resulting in more cost-efficient, but also more stable and controled shot-peening operations.

The HD cut wire range offers cost efficiency, eco-friendliness, and top-notch quality, ensuring stable peening effects with consistent particle size and hardness.

Our cut wire products are characterized by a wide range of sizes, conditioning levels, hardness options, metallurgical choices and global availability, ensuring a tailored solution for diverse blasting and peening needs.

Discover other blasting media

You may also need

We also offer and manufacture other shot media for your peening needs, such as ceramic beads, glass beads, or Ultra fine shots.