Chilled Iron Grit*

W Abrasives’ Cast Iron grit and shot, for aggressive air-blasting surface preparation.

Our cast iron abrasives have excellent performance in demanding air-blasting surface preparation tasks.

Product Overview

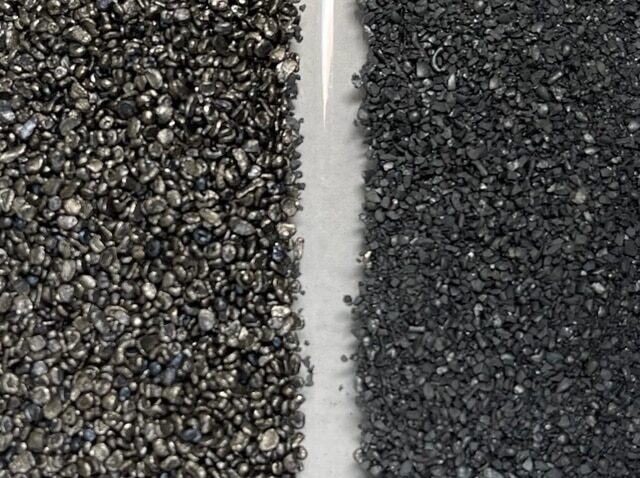

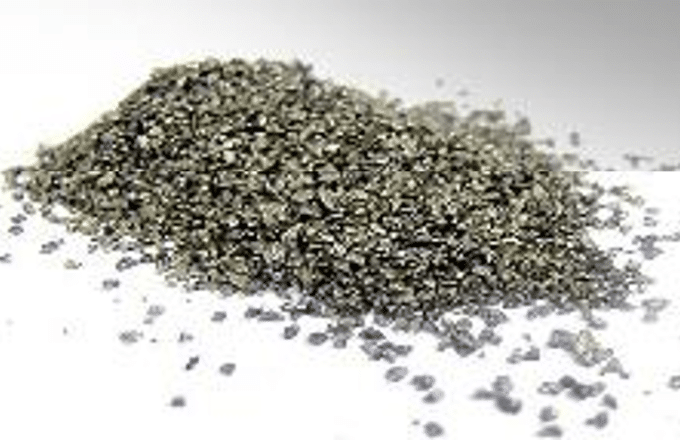

Chilled Iron (or Cast Iron) Abrasives are known for their hardness and durability, making them great for aggressive cleaning and surface preparation tasks. These abrasives are made from high-quality cast iron and undergo a chilling process to achieve their unique properties.

* Even though we continue to supply Chilled Iron Cast Steel Grit, advancements over the last 60 years have led us to recommend switching to Profilium Premium Abrasives. Profilium offers significant benefits: 15% less abrasive consumption, 20% less machine wear, improved productivity and lower Total Cost of Operation (TCO). Profilium also provides higher toughness and lower dust production, enhancing overall efficiency and cost-effectiveness.

Users benefits

Users benefits

Key features

- High Hardness: Provides great cutting power.

- Durable: Withstands repeated use compared to aluminum oxide, reducing the need for frequent replacements.

- Consistent Performance: Ensures uniform surface roughness for good coating adhesion.

- Versatile Applications: Suitable for removing rust, mill scale, and old coatings from steel surfaces.

Markets and applications

Markets and applications

Structural steel and construction

Railways

Airblast

Contractors

Specifications

Specifications

- Hardness: 650-700 HV (> 57 HRc )

- Density: >7.0 g/cm³

- Shape: Angular

- Chemical composition: %C : 2.80-3.20 / %Si : 1.40-2.00 / %Mn : 0.20-0.60 / S&P < 0.1%

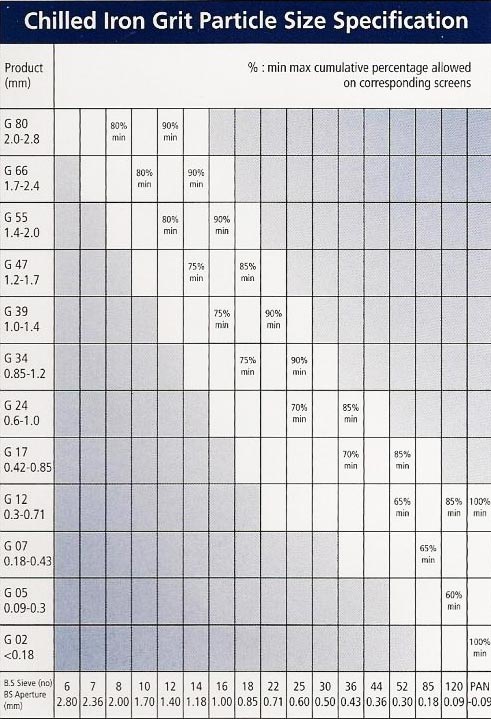

- Size Range: 0.2 – 2.0 mm

- Available grit products: G80, G66, G55, G47, G39, G34, G24, G17, G12, G07, G05, G02

Chilled Iron Grit Particle Size Specification

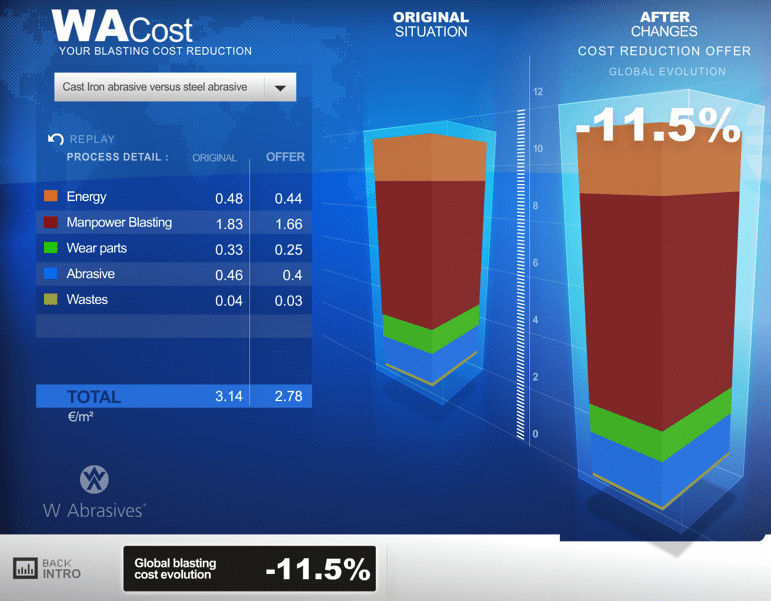

Upgrading to a Premium Steel Abrasive

Upgrading to a Premium Steel Abrasive

Profilium Grit

You may also like

You may also like

Resources & downloads

Resources & downloads