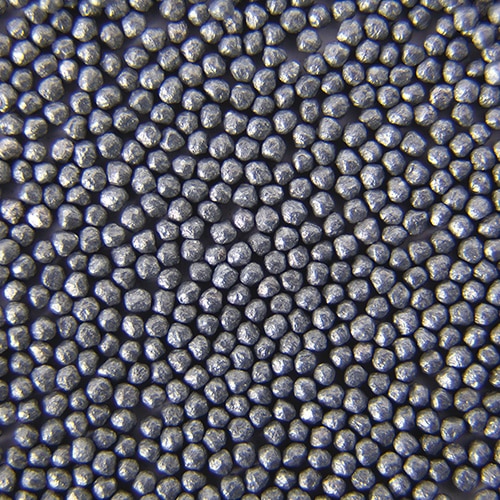

Carbon Steel Cut Wire Shot Peening Media

Precision and Performance with Frohn™ Cut Wire Solutions !

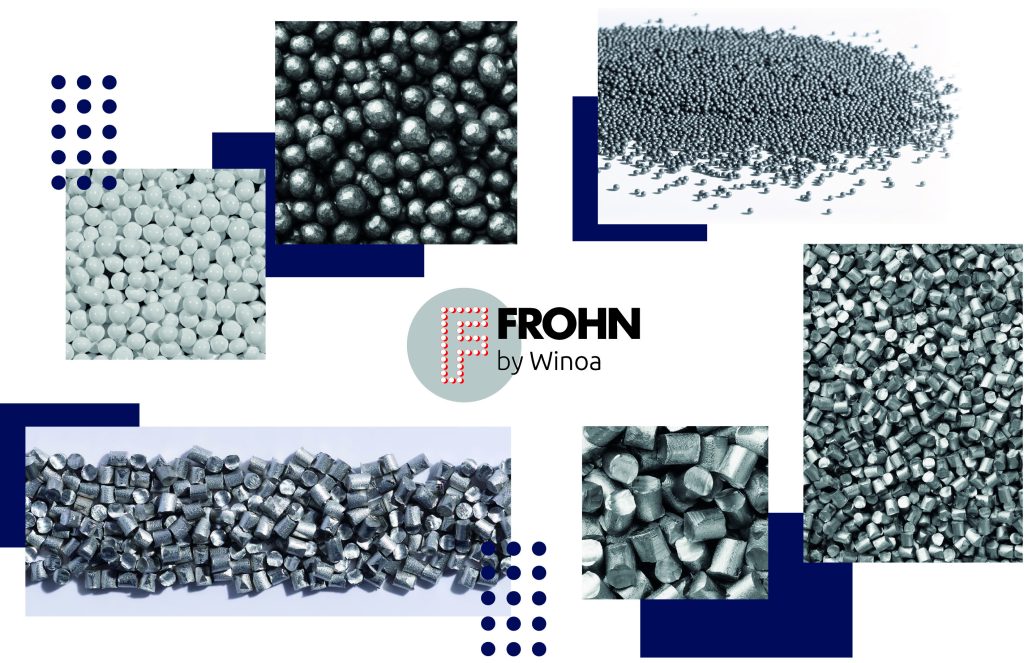

We manufacture and deliver high-spec cut wire shot peening media under the Frohn™ brand. Manufactured from high-quality carbon steel wire, Frohn™ cut wire offers great roundness, durability, and repeatability, meeting the most demanding specifications in automotive, aerospace, and industrial applications..

As-cut products can also be used in foundry and desanding applications, while conditioned cut wire is specifically designed for shot peening applications.

Users benefits

Users benefits

Why Choose Cut Wire?

Cut Wire offers several advantages that enhance your operations and deliver superior performance. Here are some key benefits:

Quality

Cut Wire is manufactured to high standards, ensuring a consistent and reliable shot media for optimal performance in various applications.

Technical assistance

Our team provides expert support to help you select and utilize the right cut wire for your specific needs, ensuring maximum efficiency and effectiveness.

Performances of cut wire

Performances of cut wire

Higher Energy

With very few flaws, cracks and voids, our metallic cut wire has the advantage of having a very high density compared to traditional shot, giving them more impact energy, which results in faster peening, cleaning or blasting.

Low breakage

Cut Wire’s manufacturing process produces little or no defects, resulting in reduced media consumption, reduced media rejects, and a lower risk of surface contamination, product impingement, and surface dust.

Constant intensity

The performance of shot peening is not only measured at an instant “T”, but by the regularity of the process. With longer lasting shot abrasives, your operational mix will be more stable over time, increasing overall peening process efficiency, including blast pattern, filtration system and finished product consistency.

Very high hardness available

A wide range of hardnesses is available, even going up to 800 HV, making cut wire ideal for all peening processes.

For all your needs

Our wide range of cut wire shot is available in steel, stainless steel, aluminum, zinc, and many other metal, from 0.25 mm to 3 mm in diameter, from very hard to extremely soft, making it the perfect solution for all your challenging blasting and most demanding peening needs.

Markets and applications of Cut Wire

Markets and applications of Cut Wire

Applications Across Key Industries

Cut Wire is widely used across various sectors due to its outstanding performance and versatility. Its superior qualities make it an ideal choice for enhancing the durability and functionality of components in several critical industries:

Automotive

Enhances precision in peening automotive parts, providing superior surface finish for critical components like engine blocks, gears and springs.

Aerospace

Delivers consistent results in preparing surfaces for high-performance coatings and peen forming, ensuring durability and corrosion resistance in extreme environments.

Oil & Gas

Strengthens critical oil and gas components by enhancing fatigue resistance by peening, ensuring long-term durability in high-stress environments such as pipelines and drilling equipment.

Conditioning Levels of Cut Wire

Conditioning Levels of Cut Wire

Different Levels of Conditioning

Cut wire is typically available at various conditioning levels. Conditioning improves its durability, but also makes sure to reduce risks of denting parts.

The characteristics of the 4 conditioning levels are :

- CW – As Cut

- G1 – Single Conditioned (CCW)

- G2 – Double conditioned (DCCW)

- G3 – Spherically conditioned SCCW)

Overall, the level of conditioning for cut wire will depend on your specific application and requirements. By choosing the right level of conditioned cut wire, you can ensure that you are using the most effective and efficient abrasive for your particular needs.

Specifications of Cut Wire

Specifications of Cut Wire

Standard Range and Custom Options

Below you will find the standard range of our regular cut wire shot media, which includes various dimensions and hardness levels to meet your needs. For specific requirements, additional dimensions, hardness options, and custom specifications are available upon request

| Carbon Steel CUT WIRE Technical specifications |

||||

| Product name & Nominal size (Sieve #) (Other sizes available upon request) |

CW-12

CW-14 CW-17 CW-20 CW-23 CW-28 CW-32 |

0.3mm diam

0.35mm diam 0.4mm diam 0.5mm diam 0.6mm diam 0.7mm diam 0.8mm diam |

CW-35

CW-41 CW-47 CW-54 CW-62 CW-71 CW-80 |

0.9mm diam

1.0mm diam 1.2mm diam 1.4mm diam 1.6mm diam 1.8mm diam 2.0mm diam |

| Available Specifications | VDFI 8001 – ISO 11124-1 – AMS2431/3 – AMS2431/8 -AMS-S-13165 (DIN 8201-4) – SAE J441 – GE-Spec – BAC-Spec Other specifications upon request |

|||

| Chemical composition available | High-carbon Steel

Low-carbon Steel 1.0517 (C48D) Other materials on request Stainless steel 302, 304, 430 Aluminum CW Zinc CW Other chemistries upon request |

|||

| Hardness Range

(Steel) |

45-52 HRc (AMS) – 55-62 HRc (AMS)

400 HV up to 830 HV 0.5/1 610 HV0,5/1 – 670 HV0,5/1 Other hardness ranges upon request |

|||

| General shape | CW – As Cut

CCW – Single Conditioned (G1) DCCW – Double Conditioned (G2) SCCW – Spherically Conditioned (G3) |

|||

| Packaging | Typically: 25kg bags on pallet – 800/900/1000 kg steel drum – 500/1000 kg big bag | |||

Explore additional Frohn™ CW peening media variants

Explore additional Frohn™ CW peening media variants

While carbon steel cut wire is the industry standard for peenig, we also offer specialized variants for your unique applications:

- 🔗 High-Durability Cut Wire (HD): Heat-treated for 30% longer life, lower dust

- 🔗 Stainless Steel Cut Wire: Corrosion-resistant for harsh environments

- 🔗 Zinc Cut Wire: Ideal for aluminum and non-ferrous components

- 🔗 Aluminum Cut Wire: Low-density media for softer substrates

Frequently Asked Questions (FAQ) about cut wire

Frequently Asked Questions (FAQ) about cut wire

Exploring common inquiries on cut wire

Cut Wire shot reduces waste due to its durability and long lifespan, leading to fewer replacements and less environmental impact

Cut wire’s consistent performance and high energy impact result in faster and more efficient cleaning and peening processes, reducing overall operational time.

Yes, Cut Wire is suitable for automated shot peening systems, providing reliable and consistent results in automated environments.

Factors such as the specific application, desired durability, and risk of part denting should be considered when selecting the conditioning level of cut wire.

Resources & downloads

Resources & downloads