Long-standing expertise in Shot Peening Media

Shot peening media

Enhancing component life with shot peening

Shot peening is used in blasting operations. It is a cold working process in which the surface of a workpiece is bombarded with small spherical particles to remove residual tensile stresses and/or add compressive stresses to the workpiece.

As a result, the use of shot peen increases the life of many components by eliminating residual tensile stress and resisting applied tensile stress.

The most common types of media used in shot peening are available

Explore our media offerings

Discover our selection of shot peening media, from the durability of high carbon steel shot to the fine finishing touch of glass beads.

Winoa's expertise in shot peening

Designed for effective shot peening

WINOA is the international leader in its market and offers unique expertise in products, services and technologies dedicated to shot peen. Shot peening is a high-value activity, certainly the most technical of all metal abrasive applications.

It is very important to know and control the blasting media used in order to:

- Meet the specified requirements

- Maintain a constant intensity

- Prevent damage to the surface

Hence the importance of working with the leading player in shot peen products for many years!

WINOA’s expertise and know-how are key factors of success to reach the high level of requirements you expect, for all your industrial peening applications, including the most demanding.

Nature of shot peen media

Media offerings

Shot peening is highly advantageous when:

Shot peening induces a large magnitude localized compressive stress to compensate for the stress concentration factor created by these geometric changes.

Compressive stress is directly correlated to the tensile strength of the material, the higher the tensile stress, the more compressive stress can be induced.

Hard/high strength metals tend to be more brittle and susceptible to notching. These conditions can be overcome by shot peen, allowing these metals to be used under fatigue conditions.

Among others, these are the most common treated materials by shot peening:

- Carburized steels

- Decarburized steels

- Austempered Ductile Iron

- Cast Iron

- Aluminum Alloys

- Titanium

- Magnesium

Contact us to review your peening application with an expert

Shot peening applications

To extend the lifespan of components

Shot peening is used in many critical operations, which guarantee the performance and longevity of the treated parts. Our experts will be able to support you for all these applications:

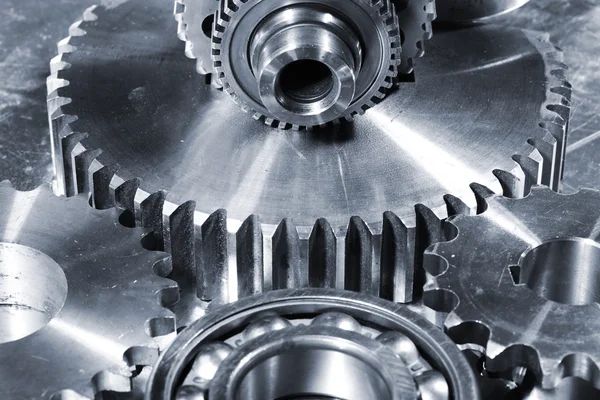

Bending fatigue

- Gears

- Connecting rods

- Crankshafts

Torsional fatigue

- Compression springs

- Torsion bars

- Drive shafts

Fretting failure

- Pitting

Corrosion failure

- Corrosion fatigue

- Stress corrosion cracking

- Intergranular corrosion

Other applications for shot peening

More to discover

Peen forming:

- The preferred method for shaping aerodynamic contours on aircraft wing skins. Residual compressive stress elastically stretches the peened side, with coverage being a non-critical parameter.

Contour correction:

- Utilized for correcting unfavorable geometry conditions by selectively shot peening specific locations on parts. Examples include straightening driveshafts/crankshafts, correcting roundness in ring-shaped geometries, addressing welding distortions, and adjusting aircraft wing stiffeners.

Thermal fatigue:

- In thermal fatigue applications, shot peening plays a crucial role in enhancing the resistance of materials to cyclic heating and cooling. This process helps mitigate the detrimental effects of thermal cycling on components, promoting longevity and reliability.

Axial fatigue:

- For axial fatigue, shot peening is employed to improve the fatigue life of components subjected to axial loading. The induced compressive residual stress reduces the risk of crack initiation and propagation, contributing to enhanced durability and performance.

Shot peening dedicated service and tools offered

More Than Just Peening Media

In addition to offering a full line of peening media, we offer parts, tools and service that will help you with your peening process

Parts and tools offered to complement our peening line:

- Coverage rate : Coverage strips, WA Pack, coverage rate simulator

- Almen Intensity : Almen strips, WA Pack including Almen gauge, Almen saturation curve solver

- Roughness : Perthometer for roughness level measurement

- Residual Stress : Possibility of outsourcing residual stress analysis for our customers, Residual stress simulator

Shot peening services offered by W Care teams:

- Peening process training & know-how

- Optimization of peening equipment to reduce costs

- Partnerships for process improvement

Frequently Asked Questions (FAQ) about shot peening

Key inquiries in sot peening media

Shot peening is used in blasting operations, utilizing small spherical particles to eliminate residual tensile stress and enhance the life of components.

Shot peening media works by bombarding the surface of a workpiece with small spherical particles, creating compressive stresses and improving component longevity.

No, shot peening is a cold working process that enhances component life by inducing compressive stresses, without removing material from the surface.

Shot blasting is a surface cleaning process, while shot peening is a cold working process that enhances component life by creating compressive stresses.

Shot peening increases hardness indirectly by inducing compressive stress, improving material resistance to fatigue and surface damage.

Shot peening can be checked using tools like Almen strips, an Almen gauge, or automated Coverage Checker to ensure consistent and controlled peening.