Shot Blasting Solutions for Application

What is shot blasting?

Blastwheel or compressed air shot blasting

Shot blasting is the projection of an abrasive onto a surface, mechanically or using air or a fluid, to remove debris, enhance the product’s properties, and/or create the desired surface finish.

Here are the 2 main systems used to project the abrasive:

Compressed air blasting and water jet sandblasting:

The method involves moving an abrasive or a shot over a surface using air or water at very high pressure, through a hose. The fluids are air or water. Generally, this mixture is projected using a set of compressors, a blast pot, flexible hoses, and a nozzle (i.e.: Clemco, Empire, Schmidt, etc.). The main advantage of compressed air blasting is that it is a low-cost way to clean and prepare surfaces, in an industrial environment or outdoors. It also produces a concentrated blasting surface.

Turbine blasting:

A turbine blaster uses a motor to propel abrasive materials at high speeds for effective cleaning or surface preparation. It’s also called Wheel blast or Wheelabrator. It converts energy from a motor into the abrasive’s kinetic energy, through the rotation of the impeller. Its main advantages are its speed, its ability to project a large volume of abrasive, its efficiency, and its ability to clean large parts.

How abrasives are used in your shot blast applications

Shot Blasting Applications

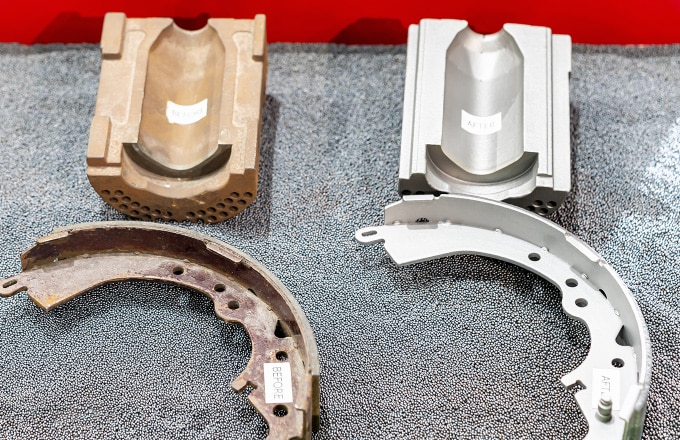

From creating profiles, removing sand from casting to reinforcing metal parts, abrasive media supports many shot blast applications.

To help categorized these shot blasting applications, we have grouped them into 5 different categories, which are: Cleaning, Preparation, Peening, Cutting and finally, miscellaneous applications requiring an abrasive media.

What is abrasive blasting ?

Abrasive blasting refers to a high-pressure stream of abrasive media on surfaces to shape it or provide a texture such as rough or smooth. It’s mainly used in industry before painting, coating, resurfacing or just as finishing. Unlike shot blasting, which specifically uses steel shot or grit, abrasive blasting can employ a wider range of materials such as sand, glass beads, aluminum oxide or even walnut shells, allowing for a more diverse application across different surface types.

Shot blasting application objectives

The shot blasting applications are many and varied, and these typical objectives are:

- Remove blemishes/rust/stains

- Thoroughly clean the metal parts

- Remove surface contaminants, including sand or scale

- Provide a specific surface profile for coating or finishing application

- Change surface properties including increased pre-stress

Ensuring a successful blasting operation

Many factors impact your steel surface preparation, such as the type of coating, abrasive or shot blasting technique. As experts for decades, we have developed technologies and methods to ensure minimal risk of coating failure– Change surface properties including increased pre-stress.

Discover our article on Paintsquare: Ensuring the Success of Blasting Operations

Frequently Asked Questions (FAQ) about shot blasting

Key inquiries in shot blast

Shot blasting involves projecting abrasive particles using either compressed air and water jet sandblasting or a turbine blaster. The abrasive’s kinetic energy helps clean, prepare, and finish surfaces efficiently.

Typical shot blasting objectives include removing blemishes, rust, and stains, cleaning metal parts thoroughly, changing surface properties, and providing a specific surface profile for coating or finishing.

In shot blasting applications, abrasives play a key role, and are used as the main tool for cleaning, desanding, descaling and enhancing surface properties. They are selected (shape, hardness, size, chemistry…) based on the specific needs of the project, whether it’s removing old paint, rust, sand or creating a texture to enhance the adhesion of new coatings. By impacting the surface with high velocity, these abrasives strip away unwanted materials and leave behind a cleaned and/or roughened surface ideal for the next steps in the surface treatment process. This makes abrasives pivotal in achieving the desired cleanliness and profile for optimal coating performance.

Shot blasting offers a versatile, low cost, environmentally friendly and effective solution for surface preparation, cleaning and descaling , addressing a wide range of applications with speed, precision and efficiency. It’s also a solution in reducing the need for harsh chemicals and minimizing waste verus using expandable abrasives. Explore the benefits of shot blasting by contacting us for optimal results.

Shot blasting plays an important role in effective surface preparation, efficiently eliminating contaminants and achieving the desired profile for coating application. When executed with precision and expertise, it significantly minimizes the risk of coating failure. Maintaining a high degree of control and cleanliness through shot blasting drastically lowers the chances of blistering, delamination, and corrosion beneath the coating, thereby enhancing the durability and longevity of protective systems.

“Blast media” refers to the abrasive material projected during shot blasting, such as steel shot or steel grit, playing a crucial role in achieving the desired surface finish.

There are two main systems: compressed air blasting with air or water at high pressure, and turbine blasting using a wheel blaster to convert electrical energy into kinetic energy for efficient surface cleaning.

Abrasive blasting involves using a high-pressure stream of shot or grit on surfaces to shape or texture them, commonly used in industrial processes for surface preparation before coating.