Low Carbon Cast Steel Shot by W Abrasives™

W Abrasives™ high durability, low dust, reusable & recyclable low carbon steel shot media

*ONLY AVAILABLE IN NORTH AMERICA*

Low carbon cast steel shot, suited for simple foundry cleaning applications, desanding, deburring or descaling. With its typical lower hardness, this media has a good resistance to breakdown, could reduce machine wear while maintaining its effectiveness for many demanding industrial applications like removing sand or scale from castings.

Users benefits of low carbon steel shot

Users benefits of low carbon steel shot

Unique features

Low carbon cast steel shot offers several unique benefits that enhance its performance and application versatility:

100% recyclable

Low carbon cast steel shot is fully recyclable, making it an environmentally friendly choice that supports sustainability in industrial processes.

Homogeneous microstructure

This media features a consistent microstructure, ensuring uniform performance and reliability across various applications.

High Durability

Despite its lower hardness, low carbon cast steel shot provides high durability, contributing to reduced machine wear and extended media lifespan.

Low-carbon steel shot: performances

Low-carbon steel shot: performances

Applications and advantages

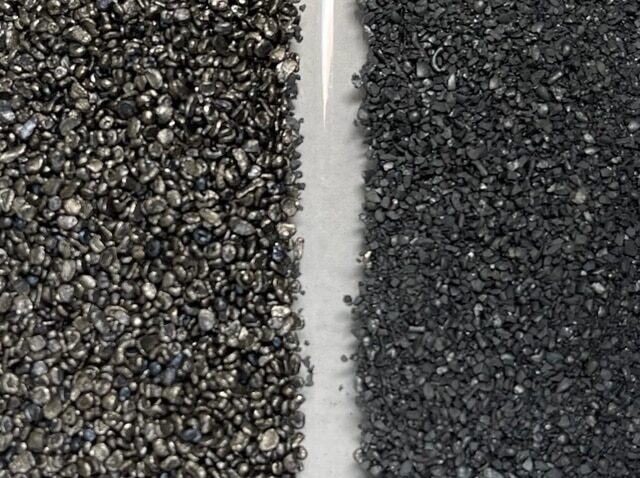

Good cleaning performance with durable microstructure:

Low carbon cast steel shot is produced using low sulfur and phosphorus steel scrap. Its bainite microstructure results in a long-lasting, robust, and nearly defect-free shot media, delivering good cleaning and desanding performance.

Superior quality vs other low carbon manufacturers:

Manufactured according to SAE J2175 & J444 specifications, our low carbon cast steel shot is produced using a new and cutting-edge (‘2022) production line. This advanced technology manufacturing site ensures the highest quality, manufacturing control, efficiency, and minimal environmental impact in compliance with the latest standards.

Versatile size options to meet specific requirements:

An important range of standard sizes, including S110, S170, S230, S280, S330, S390, S460, S550, and S660, is readily available to answer to various industry needs. Additionally, we offer larger sizes, such as S780 or S930, and smaller sizes like S070 upon request to accommodate specific requirements.

High production quality control:

Manufactured to exceed SAE J2175 standards, our low carbon media will meet a hardness between 40 and 51 Rockwell C (500-540 KNH), with a low level of defects (shape, cavities, cracks), as well as a microstructure well within the industry standard.

Markets and applications of low carbon cast steel shot

Markets and applications of low carbon cast steel shot

Versatile and performing across many industries

Low carbon cast steel shot is highly versatile and effective across various industries, providing reliable performance and durability: automotive casted parts, railway bogie parts, wind power system and foundries. Additionally, it is highly effective in the forging industry, die casting, heat treating, bar drawers, farm equipment, aluminum processing, ship manufacturing, and engine and turbine manufacturing.

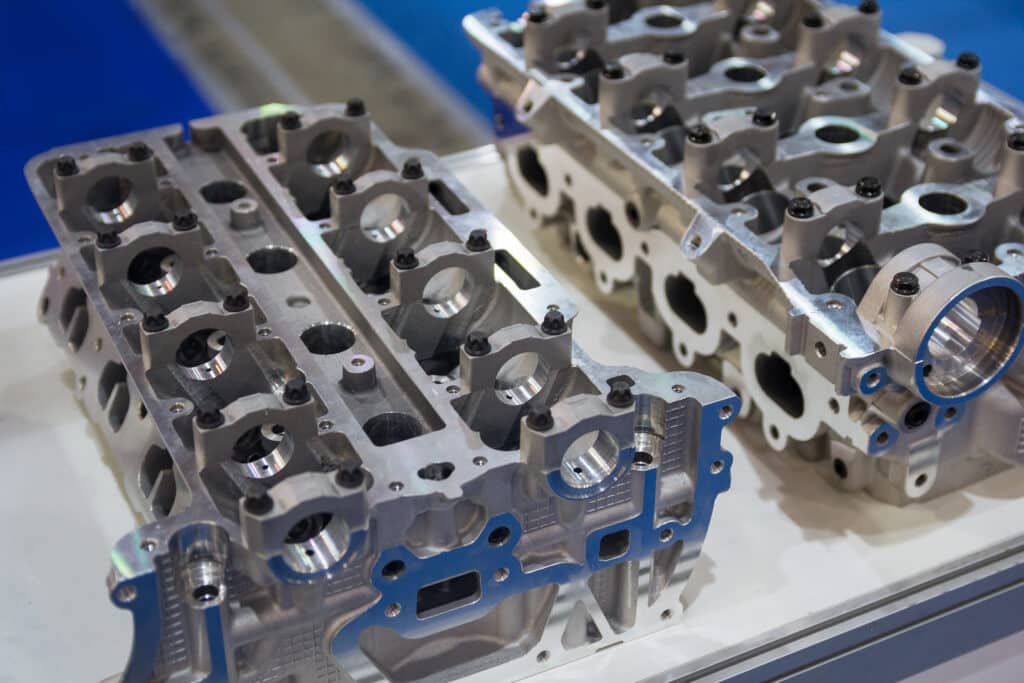

Automotive casted parts

Railway bogie parts

Wind power system

Foundries

Specifications low carbon abrasives

Specifications low carbon abrasives

Detailed Overview

Below is a detailed overview of the low carbon cast steel shot specifications. This table outlines the essential characteristics and available options for this media, ensuring you have comprehensive information to make informed decisions.

| Family | Low Carbon Steel Shot |

| Shape | Round |

| Shape in operation | Round |

| Chemical composition | C: 0.10–0.15%, Si: 0.10–0.25%, Mn: 1.20–1.50%, Al: 0.05–0.15%, S: ≤0.035%, P: ≤0.035% |

| Hardness | 40-50 HRC (400-540 HV) |

| Standard deviation | ± 3 HRc (± 40 HV) |

| Microstructure | Bainitic microstructure |

| SAE Sizes Available | S-780, S-660, S-550, S-460, S-390, S-330, S-280, S-230, S-170, S-110, S-70 |

| Density | Minimum 7 g/cc |

| Packaging | BOXED BAGS

DRUM BIG BAG (2000 lb & 4000 lb)

|

Meets and Exceeds the following specifications: SAE J2175 (Low Carbon Cast Steel Shot Specifications), SAE J444 (Cast Shot Size), SAE J445 (Mechanical Testing) and other specifications upon request…

Size distribution of low carbon abrasives

Size distribution of low carbon abrasives

Detailed sizing information

The size distribution of low carbon abrasives is for selecting the appropriate media for your application. Below is a comprehensive table showing the size ranges for various products:

(Primarily used in Americas and Asia)

|

Product |

7 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

80 |

120 |

200 |

| S780 |

AP |

85%

min |

97%

min |

||||||||||||||

| S660 |

AP |

85%

min |

97%

min |

||||||||||||||

| S550 |

AP |

85%

min |

97%

min |

||||||||||||||

| S460 |

AP |

5%

max |

85%

min |

96%

min |

|||||||||||||

| S390 |

AP |

5%

max |

85%

min |

96%

min |

|||||||||||||

| S330 |

AP |

5%

max |

85%

min |

96%

min |

|||||||||||||

| S280 |

AP |

5%

max |

85%

min |

96%

min |

|||||||||||||

| S230 |

AP |

10%

max |

85%

min |

97%

min |

|||||||||||||

| S170 |

AP |

10%

max |

85%

min |

97%

min |

|||||||||||||

| S110 |

AP |

10%

max |

80%

min |

90%

min |

|||||||||||||

| S70 |

AP |

10%

max |

80%

min |

90%

min |

|||||||||||||

| Screen Number |

7 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

80 |

120 |

200 |

| Screen Size (mm) |

2.80 |

2.36 |

2.00 |

1.70 |

1.40 |

1.18 |

1.00 |

0.85 |

0.71 |

0.60 |

0.50 |

0.425 |

0.355 |

0.30 |

0.180 |

0.125 |

0.075 |

| Screen Size (inches) |

0.111 |

0.0937 |

0.0787 |

0.0661 |

0.0555 |

0.0469 |

0.0394 |

0.0331 |

0.0278 |

0.0234 |

0.0197 |

0.0165 |

0.0139 |

0.0117 |

0.007 |

0.0049 |

0.0029 |

Frequently Asked Questions (FAQ) about low carbon cast steel shot

Frequently Asked Questions (FAQ) about low carbon cast steel shot

Exploring common inquiries and expert insights

Low carbon cast steel shot is primarily used in foundry cleaning applications, desanding, deburring, and descaling. It is suitable for removing sand or scale from castings in various demanding industrial processes.

This media offers high durability, reduces machine wear, and maintains effectiveness in industrial applications. Its low hardness helps minimize breakdown and supports sustainability through its recyclable nature.

Yes, low carbon steel shot is 100% recyclable, making it an eco-friendly choice that supports sustainability in various industrial processes.

Low carbon cast steel shot is available in a range of standard sizes, including S110, S170, S230, S280, S330, S390, S460, S550, and S660. For specific applications, larger sizes such as S780 and S930, as well as smaller sizes like S070, can be provided upon request.

Our low carbon cast steel shot is manufactured using advanced technology and a cutting-edge production line, ensuring high quality, manufacturing control, efficiency, and minimal environmental impact in compliance with the latest standards.

For improved cleaning efficiency

For improved cleaning efficiency

You may also like

Resources & Downloads

Resources & Downloads