3D Surface Profile Technology

Why ask for Surface Profile 3D Tech roughness?

Preparing metallic component surfaces often requires precision. Surface Profile 3D Tech is a cutting-edge technique that measures disparities between treated areas. It supplements conventional measurements with 2D instruments. Our W Care experts provide a meticulous analysis in order to better understand your machines’ efficiency, make adjustments, and provide employee training programs.

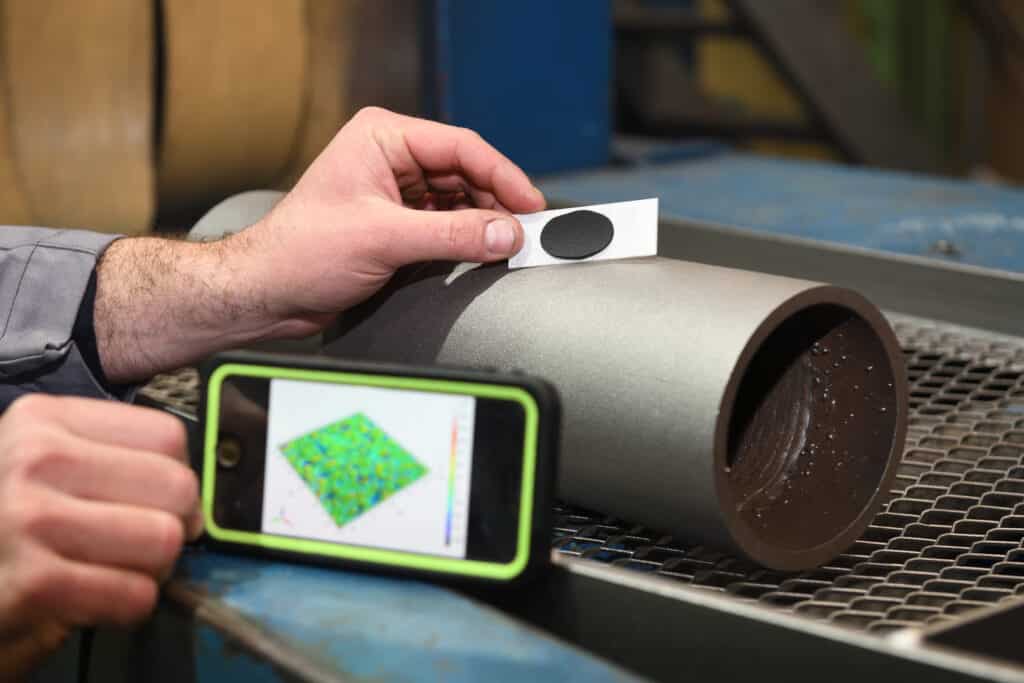

How to carry out Surface Profile 3D Tech roughness

How to carry out Surface Profile 3D Tech roughness

Discover our surface profile 3D

Advantages

Advantages

THE BENEFITS OF THE 3D SURFACE KIT

How can Surface Profile 3D Tech benefit your industrial process?

Its cutting-edge technology ensures a complete assessment of potential disparities between treated areas. In addition to conventional measurements, it provides the ability to meticulously analyze the efficiency of your machines and to create training programs that enhance your employees’ knowledge.

Winoa’s philosophy is centered on developing quality tools, which helps maintain the trusting relationship we have built with our users. Surface Profile 3D Tech services allow our WCare experts to provide you all the assistance required to satisfy your needs and to find avenues for improvement.

What does a Surface Profile 3D Tech report show?

What does a Surface Profile 3D Tech report show?

RESULTS OF THE 3D PROFILE SURFACE KIT

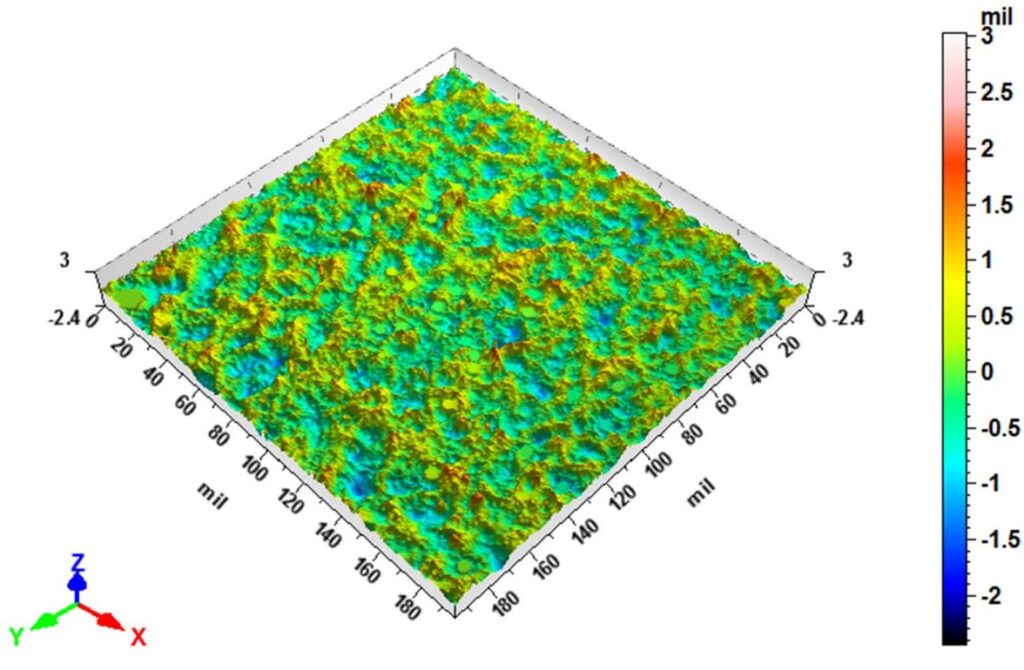

Surface Profile 3D Tech uses 2500 measurements to create a diagram. The measured results include factors such as Ra, Rz and Rmax, expressed in µm, and Rpc expressed in unit/cm.

Cut-off length must be chosen according to your needs.

Other parameters, such as Rsk and Rku, concern the coating’s resistance to wear over time. Vv, which corresponds to 2/3 of Rz, is the useful paint thickness required to cover the roughness that has been produced.

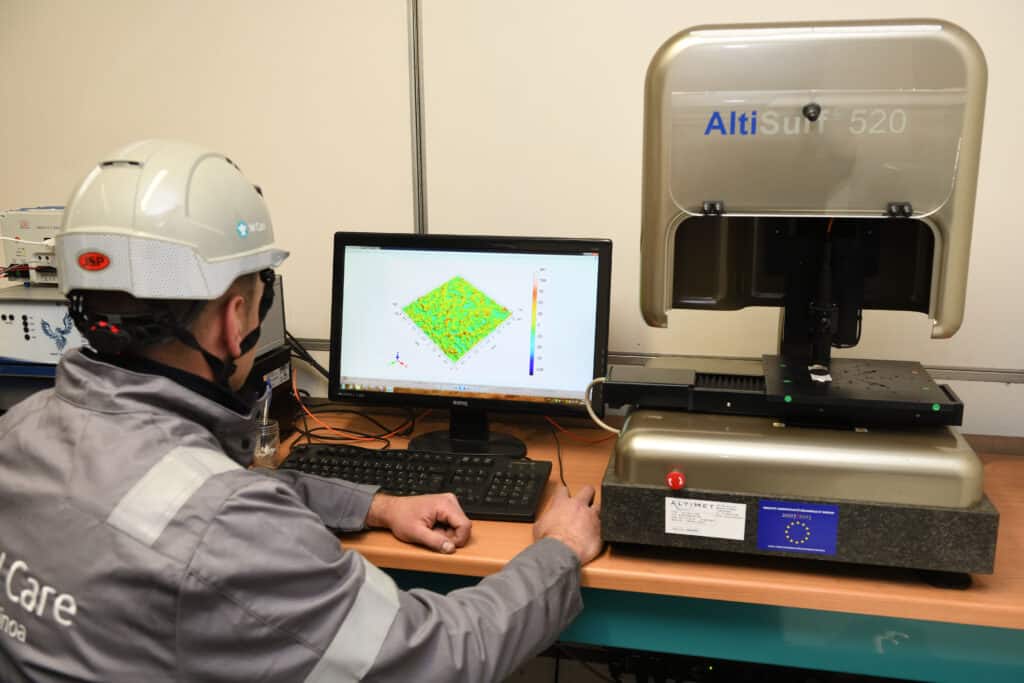

Discover our WA 3D technology

Discover our WA 3D technology

EXPLANATORY VIDEO OF THE SURFACE PROFILE 3D KIT

Discover WA3D on video, an innovative surface profile measurement solution from W Abrasives. This cutting-edge technology offers a precise, non-invasive way to assess surface profiles, ensuring accuracy, consistency, and traceability. Perfect for optimizing surface preparation and coating processes, WA3D is a game-changer in the industry.

Watch the video to learn more about how WA3D can elevate your surface preparation processes.