Our Environmental Ambitions and Commitments

Our "Green" Strategy

Our environmental ambitions and commitments

The “ESG” strategy (E: environment, S: social and G: governance) is crucial for Winoa’s growth plan. The environmental pillar is outlined in an ambitious commitment charter, notably aiming to reduce our carbon footprint “The Green Pledge”. This commitment is available to all our partners and aims at achieving carbon neutrality by 2050.

An environmental activity by nature

Our environmental ambitions

Winoa offers environmentally friendly surface treatment solutions and seeks to minimize its environmental impacts.

The exclusive use of recycled steel scrap for production, the reduction of energy and consumable needs, and the valorization of co-products generated throughout the manufacturing cycle contribute to this goal.

100% of the Group’s production sites are ISO 14001 certified (environmental management system), recognizing the relevance of the processes to make progress in terms of environmental respect.

In addition, we are committed to a proactive approach to energy efficiency, notably through obtaining ISO 50001 certifications.

"Being a responsible leader in our business"

Interview Ramesh Krishnan, CEO & Chairman

As global number one in steel abrasives, our ambition is to be a business and environmental leader. We offer environmentally friendly surface treatment solutions, and we are constantly working to reduce our environmental impact

Ramesh Krishnan, CEO & Chairman

Winoa is a responsible global leader

Our commitments

Furthermore, 95% of our raw materials come from recycling, 80% of our waste is valorized, and our abrasives can be reused thousands of times before being remelted. An ambitious energy efficiency program in production has been implemented. Whether it’s major investments, such as innovative heat treatments, or more modest measures, like LED lighting in workshops, we seek all levers.

Every degree, every kilowatt counts towards reaching our goal. We are also studying carbon capture technologies. In a comprehensive approach to the environment, we also work in partnership with our customers. We focus on cutting-edge products and services to reduce the environmental impact during the use of our products. Our committed suppliers become reference partners. Moreover, we are building digital expertise, essential to ensure our environmental leadership. Winoa is a responsible global leader. Our expertise and passion help us fulfill our commitments to the planet.

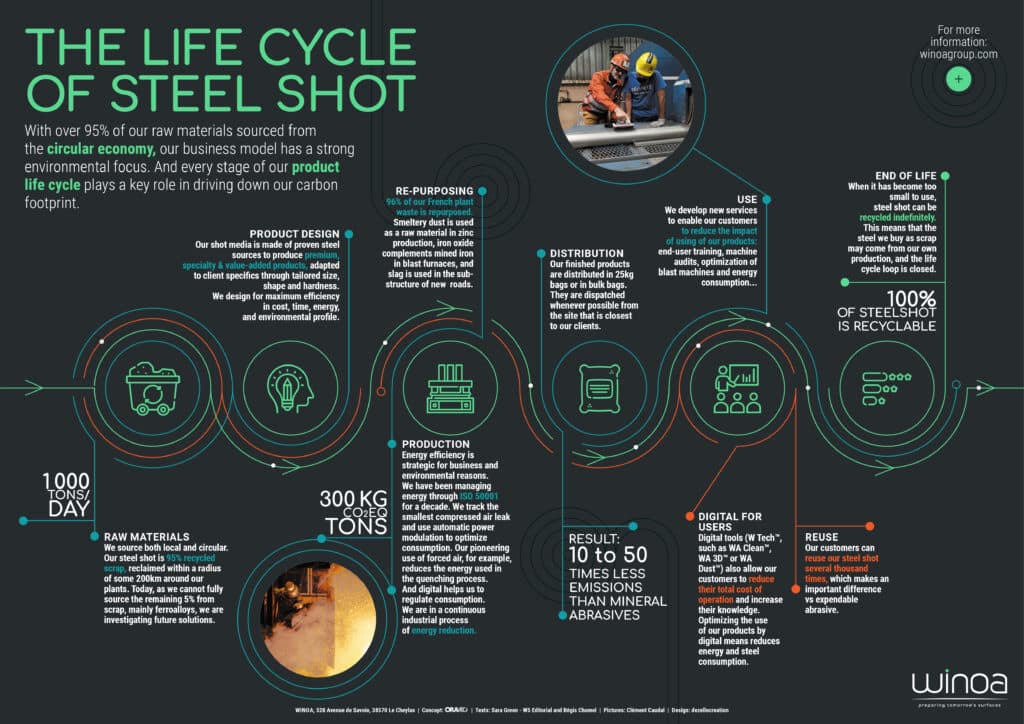

The life cycle of steel shot

Discover the life of our products

With over 95% of our raw materials coming from the circular economy, our business model is strongly environmentally focused. And each stage of the life cycle of our products plays a key role in reducing our carbon footprint.

Our actions

ISO 50001 for energy reduction

Our environmental ambitions

“Unused energy improves our energy balance!” This common-sense approach guides our processes and actions. So much so that we have had it ISO50001 certified. We apply this system all over the world and in all our activities, including our upstream energy purchases.

Discover our strategy in video