Stainless steel shot abrasive range

Why use stainless steel shot?

Industries that benefit

Stainless steel abrasive media are among the most commonly used blasting materials in metallurgy due to its specific properties, especially corrosion resistance and iron-free contamination. The metallurgy, light metal, oil & gaz, automotive, aerospace and wind power industries are among the sectors that make the most use of this type of blasting material. As a privileged partner of its customers in continuous innovation and quality, Winoa has a wide range covering the needs inherent to each production.

A wide range of products for stainless steel abrasive

Spherical shot or angular steel grit

Advantages of stainless steel media

Cleanliness, durability, economic

Cleanliness

Longer coating durability

Roughness

Better coating adhesion

Process control repeatability

Higher quality consistency

User benefits of stainless steel abrasive

Cost efficiency

Stelux stainless steel shot & grits have many advantages over metallic and non-metallic or expandable abrasives.

In addition to having a much lower cost of use than non-recyclable media (when a process for reusing the media exists), these have:

- Considerably increased durability, allowing reuse up to 1000 times

- Higher mass of each grain, which increases energy and cleaning efficiency and speed

- Less machine wear, thanks to its hardness just below the equipment components

- Reduces or could avoid using chemical cleaning or acid pickling processes

- Eliminates the possibilities of having embedded iron particles, avoiding rusting & pitting

- Leaves a thin passive layer that prevents surface corrosion due to the chromium in the medias well as almost zero dust blasting production

Customized options on Winoa stainless steel media

Features and descriptions

Your requirements are unique? So is our expertise! Here are a few examples of the options we create for our clients with Stelux™ stainless steel abrasive media range. To be able to meet the majority of requirements, from a rough profile to a high nickel content option, Stelux™ range will be able to respond to your needs:

Stainless steel shot: a wide range of applications

Broad Spectrum of Uses

Our stainless steel shot is designed for a wide array of applications, meeting diverse needs across various industries.

Metal treatments

- Galvanized steel, non–ferrous metals / casting & parts

- Stainless steel, nickel based, zinc & titanium alloys

- Castings, forgings and welded parts

Surface preparations

- Prior powder coatings, painting

- For insulation prep

- Roughening surfaces prior to bonding

- Removal of weldment bluing and surface finishing

Cleaning & removal

- Brush blasting for “white rust” removal (zinc oxide)

- Paint removal

- Surface preparation & cutting in wet environment

Specialized processes

- Removal of heat treatment scales, forgings & castings released agents

- Preconditioning step prior to chemical process or acid pickling

- Ceramic removal & finishing for investment castings

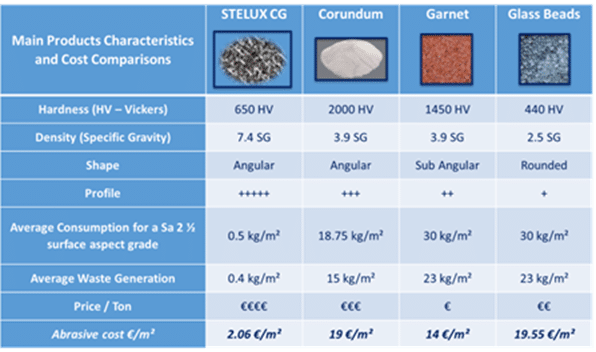

The economic benefit of using stainless steel shot

Why Choose Stelux™ Stainless Steel Grit or Shot?

With significantly lower consumption rates than expandable media, the total cost of “sandblasting” can be reasonably 5 times less using a Stelux™ stainless steel grit or shot product than any other expanding abrasive when using a recycling system.

At similar effectiveness for prepared surfaces, the main savings come from:

- Costs of disposal of dust and used abrasives

- Media consumption

- Maintenance costs

Not to mention increased efficiency through better visibility, better room cleanliness and happy employees!

Frequently Asked Questions (FAQ) about stainless steel shot abrasive

Explore key inquiries on stainless steel shot for optimal blasting

Stelux™ stainless steel shot stands out for its exceptional durability, corrosion resistance, iron-free contamination and significantly lower cost of use compared to expandable abrasives, providing an economical and efficient solution.

Stainless steel shot is used in a wide range of applications, including metal treatments, surface preparations, cleaning, paint removal, and various specialized processes in industries such as automotive, aerospace, metallurgy, and wind energy.

Benefits include improved recyclability vs expandable abrasives and being iron-free contamination, better coating adhesion, increased shot durability, reproducible process control, and excellent surface and shinny finish quality, making stainless steel shot an ideal choice for metallurgical applications.

Advantages include significantly increased durability, reduced costs related to dust, better visiblity improving working speed, and used abrasive disposal, lower machine wear, and increased energy and cleaning efficiency.

Above leaving an iron-free blasted surface, by eliminating the possibility of embedded steel shot particles in metal surfaces, stainless steel shot prevents rust points on high-value items such as steel frames of recreational vehicles or car-hauling trailers.

Stelux™ offers customized sieving and blend options, ranging from rough profiles to high-nickel content options, to meet the unique requirements of customers in the field of stainless steel abrasive media.

Stelux C and Stelux CN spherical shot are ideal for stripping aluminum and cleaning welds on stainless steel structures, due to their specific hardness, mass and being iron-free, ensuring optimal results while preserving the integrity of the treated materials.

Success Stories

Learn More

Discover TMB’s exceptional surface finishing process using W Abrasives Stelux media from Winoa