Shot peening

What is shot peening?

The science behind peening

Shot Peening is as simple as the process of shot blasting, but with a perfectly controlled process, creating a high value activity, the most technical one among metallic abrasives applications. Winoa’s expertise and know-how are key factors for your success in reaching this application’s high level of performances.

Shot peening process is used in multiple industries to extend the service life of a component. The process induces a compressive stress layer to increase resistance to fatigue (propagation of cracks, stress corrosion, etc).

To name a few, peening are used on automotive parts (gear, cams, clutch, coil and suspension spings) to aerospace (landing gears to turbine blades), energy sector (rock drills and windmill gears) to Railcars (wheels and coupling peening) and many others.

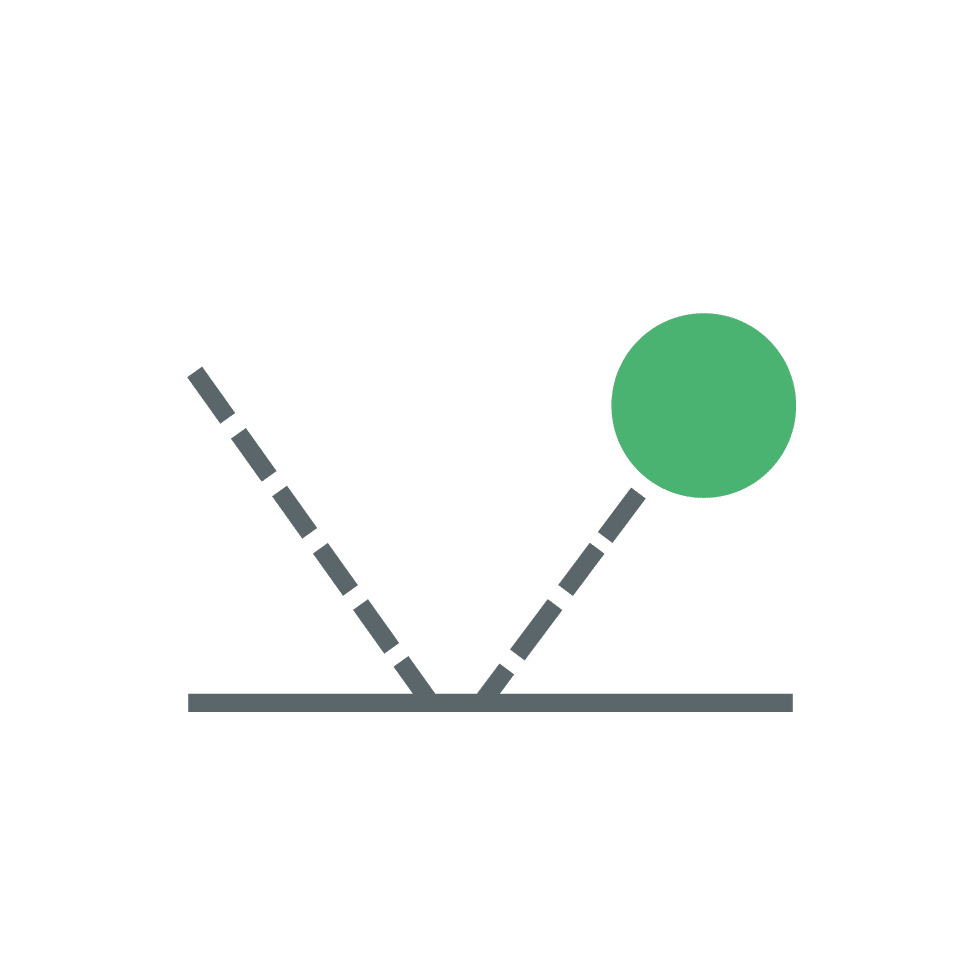

Understanding the Science of Peening

Enhancing durability through advanced surface treatment

The Benefits of Peening

Enhancing material performance and longevity

Peening is a crucial surface treatment process that offers several technical benefits, significantly improving the performance and durability of metallic components. Below, we detail the key benefits of peening

Enhanced Fatigue Resistance

Tensile Stress Mitigation:

- Mechanism: Peening induces compressive residual stresses on the surface layer of materials. These compressive stresses counteract the tensile stresses that typically cause fatigue failure.

- Benefit: By mitigating tensile stresses, peening significantly extends the fatigue life of components, making them more resilient under cyclic loading conditions.

Improved Stress Corrosion Resistance

Cracking Resistance:

- Mechanism: The compressive stresses introduced during peening reduce the tensile stresses that contribute to the initiation and propagation of stress corrosion cracks.

- Benefit: This results in a substantial reduction in the susceptibility of materials to stress corrosion cracking, particularly in aggressive environments, thus enhancing the overall durability of components.

Increased Wear Resistance

Surface Hardening:

- Mechanism: The repeated impacts during the peening process cause strain hardening of the surface layer, increasing its hardness.

- Benefit: The hardened surface is more resistant to wear and erosion, improving the component’s performance in abrasive environments and extending its service life.

Specifications for shot peening

Discover our specifications

Most suitable shot peening products

Peening solutions

Specifically, for shot peening, we have developed 3 steel products meeting the highest standard of quality.

Optimization for shot peening

Moreover, in order to optimize the complex shot peening process, it is not enough to have a good shot, you need the tools and accessories to control the peening.

To do this, trust our peening accessories. Whether it’s W Abrasives Almen strips to the Almen strip holder, or the Almen Gauge to an automated Coverage Checker made by our partner Toyo Seiko, trust our experts to advise you on our tools.

Additional Services for Your Peening Needs

Comprehensive support

At Winoa, we not only provide high-quality peening shots and instruments, but also offer comprehensive support to enhance your operations and skillset. Our team can assist with the inspection and maintenance of your peening equipment, ensuring optimal performance, reliability, and longevity. Additionally, we offer specialized peening services at some of our tech centers. This global approach ensures you achieve the best possible results from your peening processes, tailored to meet your specific requirements.

Frequently Asked Questions (FAQ) about peening

Key inquiries in peening

Shot peening extends the service life of components across various industries, inducing a compressive stress layer to enhance resistance to fatigue, stress corrosion, and other detrimental effects.

Shot peening offers benefits such as increased component life, resistance to fatigue, and improved material properties, crucial in various industries.

Shot peening may face limitations if a component’s surface is too hard or if the surface temperature surpasses the metal’s normalizing temperature, leading to the loss of crucial residual compressive stresses. Moreover, the process demands an open surface for direct shot impingement, posing challenges when dealing with blind or inaccessible areas.

The ISO-26910 standard provides international guidelines for shot peening processes, ensuring industry-wide quality and consistency. For the shot media used, standards such as SAE AMS2431, SAE J444, and ISO 11124 provide detailed specifications on the media’s physical properties like shape, size, and hardness. These standards are crucial for achieving effective shot peening results, enhancing the durability and fatigue life of treated components by ensuring the media used meets rigorous quality criteria. Compliance with these standards guarantees the integrity and effectiveness of the shot peening process.

AMS 2430 & 2431: These are aerospace material specifications that cover the requirements for shot peening processes and peening media used in the aerospace industry. AMS 2430 specifies the general requirements for shot peening, including procedures and quality control, while AMS 2431 provides detailed specifications for the peening media.

VDFI 8001: This is a German standard that specifies the requirements for metallic shot peening media used in various industrial applications, ensuring consistency and quality in the peening process.

ISO 26910: An international standard that outlines the requirements for peening media, focusing on ensuring global consistency and quality for peening applications across different industries.

Each standard ensures that the media and processes used in shot peening meet specific quality and performance criteria relevant to their respective industries.

Contact us

Peening solutions

To be able to select the best option and services for your peening application, please communicate with one of our specialists