Steel Grit: High Carbon Steel Grit by W Abrasives™

Long-lasting, reliable, reusable & recyclable metallic grit abrasives

Steel grit blasting abrasive, high carbon, cast, manufactured under strict quality controls and conditions, using a unique air quenching thermal process, which will deliver a long lasting media. With minimal chloride & salt concentration (the lowest on the market), you receive a blasting media with the highest impact value for your cleaning application. Used primarily in «sandblasting» for surface preparation prior to painting, it is also used for descaling and desanding applications.

Steel grit user benefits

Steel grit user benefits

3 key features

Elevate your surface preparation game with our steel grit abrasive. Our commitment to quality shines through three key features that set our product apart.

100% Recyclable

Opt for our eco-friendly steel grit blasting abrasive, crafted from high carbon steel for long-lasting efficiency. Choose sustainability without compromising performance.

Air quenched

Experience lasting strength with our air-quenched steel grit. Through a unique thermal process, our high carbon grit delivers optimal results for your cleaning needs.

Globally Available

Rely on our steel grit for worldwide accessibility, providing a consistent and dependable source for all your surface preparation needs across continents.

Performances of steel grit abrasive

Performances of steel grit abrasive

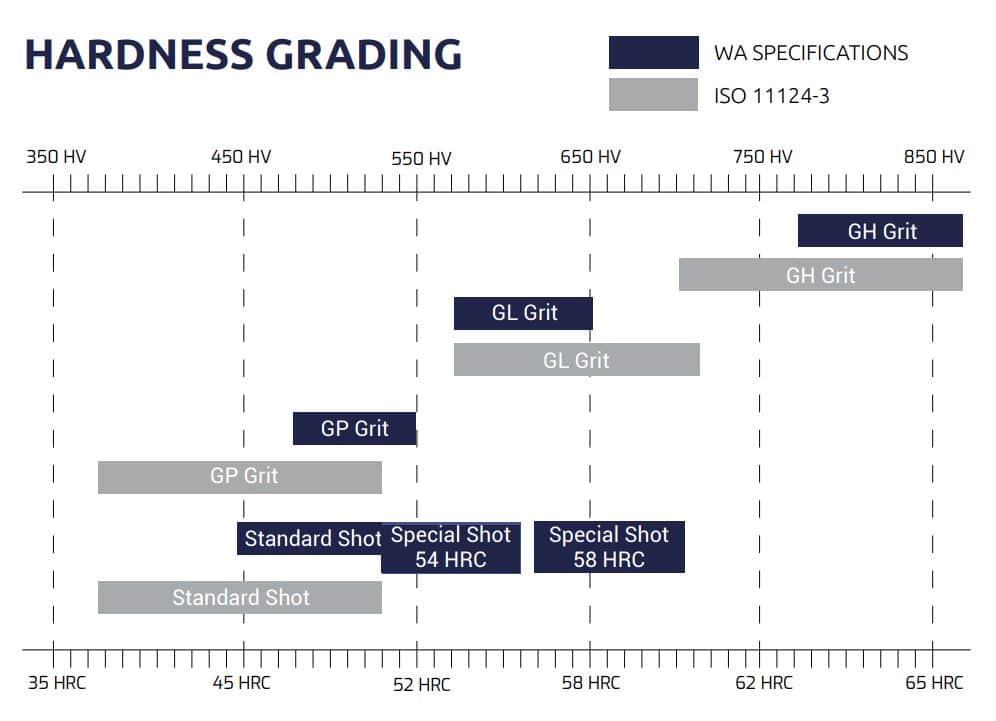

Hardness levels explained

Our steel grit abrasive takes versatility to the next level with four distinct hardness options, catering to a range of applications. From a soft range (GP), for cleaning applications using turbines, to intermediate ranges (GB and GL), for angular profiles and higher cleaning speeds, to a very hard range (GH) , for all applications requiring significant mechanical anchoring, deep cleaning, and mainly used with compressed air shot blasting.

Each line is formulated with a narrow hardness range, which means more stable, consistent, and reliable profile results for your “sandblasting” production process.

Manufactured using a unique process, our steel abrasives have chloride and salt levels below 50 μS/cm, the lowest on the market. This reduces the possibility of contaminating surfaces, ensuring longer life for coatings and paints.

A wide range of standard sizes of G14, G16, G18, G25, G40, G50 or G80 are always abailable, while larger sizes, such as G12, G10 or very small (G120) are available on request.

Hardness Levels of steel grit

Markets and applications of steel grit blasting abrasive

Markets and applications of steel grit blasting abrasive

Shot blasting at its best

Embark on a journey exploring the dynamic markets and applications of steel grit shot blasting abrasive. From reinforcing steel structures and bridges to optimizing railways, pipe coatings, windmills, metallurgy processes, and contractor projects, our steel shot blasting abrasive stands as a versatile solution, enhancing durability and efficiency across diverse sectors.

Steel structures, bridges

Railways

Pipe coating

Windmills

Metallurgy

Contractors

Specifications of steel grit

Specifications of steel grit

|

Family |

Steel Grit GP |

Steel Grit GL |

Steel Grit GH |

|

Shape |

Angular |

||

| Shape in operation | Angular “Patatoid“ | Angular “Soft edges“ | Angular “Sharp edges“ |

| Chemical composition | C ≥ 0.80%, Si ≥ 0.40%, 0.60% ≤ Mn ≤ 1.20%,

S ≤ 0.05%, P ≤ 0.05% |

||

|

Hardness |

40-51 HRC

(544-613 HV) |

54-61 HRC

(580-720 HV) |

60 HRC min

(697 HV) |

| Standard deviation |

± 3Rc (± 80 HV) |

||

|

Microstructure |

Highly refined and homogeneous tempered martensite, obtained through a well-controlled manufacturing process that mixes the iron and carbon atoms

in the finest and most ideal way possible, producing optimum homogeneity, hardness and resistance. |

||

| Minimum density measured by alcohol displacement |

> 7.3g/cm3 |

||

|

Conductivity |

Typically, <30 μS/cm

Low level according to ASTM D4940 |

||

| Applicable specifications | SAE J444, SAEJ445, SAE J1993, ASTM

D4940, SSPC-AB3 (on request) |

||

If you wish to learn more about the standards and certifications of steel grit blasting abrasive :

SAE Standards ASTM International AMPP Nace Standards ISO 11124-3:2018

Size distribution of Steel Grit

Size distribution of Steel Grit

W Abrasives™ SAE and WA size options

(primarily used in Americas and Asia)

| Steel Grit Product | Sieve opening in mm (values given in cumulated weight %) | ||||||||||||||||

| 2,8 | 2,36 | 2 | 1,7 | 1,4 | 1,18 | 1 | 0,85 | 0,71 | 0,6 | 0,5 | 0,42 | 0,35 | 0,3 | 0,18 | 0,12 | 0,07 | |

| G 12 | AP | 80% min | 90% min | ||||||||||||||

| G 14 | AP | 80% min | 90% min | ||||||||||||||

| G 16 | AP | 75% min | 85% min | ||||||||||||||

| G 18 | AP | 75% min | 85% min | ||||||||||||||

| G 25 | AP | 70% min | 80% min | ||||||||||||||

| G 40 | AP | 70% min | 80% min | ||||||||||||||

| G 50 | AP | 65% min | 75% min | ||||||||||||||

| G 80 | AP | 65% min | 75% min | ||||||||||||||

| G 120 | AP | 60% min | 70% min | ||||||||||||||

| Screen Number | 7 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 80 | 120 | 200 |

| Screen Size (mm) |

2,8 | 2,36 | 2 | 1,7 | 1,4 | 1,18 | 1 | 0,85 | 0,71 | 0,6 | 0,5 | 0,42 | 0,35 | 0,3 | 0,18 | 0,12 | 0,07 |

| Screen Size (inches) |

0,111 | 0,0937 | 0,0787 | 0,0661 | 0,0555 | 0,0469 | 0,0394 | 0,0331 | 0,0278 | 0,0234 | 0,0197 | 0,0165 | 0,0139 | 0,0117 | 0,007 | 0,0049 | 0,0029 |

(primarily used in Europe, MEIA (Middle East, India and Africa)

| Steel grit Product | Sieve opening in mm (values given in cumulated weight %) | ||||||||||||||||

| 2,8 | 2,36 | 2 | 1,7 | 1,4 | 1,18 | 1 | 0,85 | 0,71 | 0,6 | 0,5 | 0,42 | 0,35 | 0,3 | 0,18 | 0,12 | 0,07 | |

| W G12 | 0 | <20 | >85 | >97 | |||||||||||||

| W G14 | 0 | <10 | >80 | >90 | |||||||||||||

| W G16 | 0 | <10 | >80 | >90 | |||||||||||||

| W G18 | 0 | <30 | >85 | >97 | |||||||||||||

| W G25 | 0 | <40 | >85 | >97 | |||||||||||||

| W G40 | 0 | <20 | >90 | >96 | |||||||||||||

| W G50 | 0 | <10 | >80 | >90 | |||||||||||||

| W G80 | 0 | <20 | >75 | >90 | |||||||||||||

| W G120 | 0 | <10 | >50 | >80 | |||||||||||||

| Screen Number | 7 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 80 | 120 | 200 |

| Screen Size (mm) |

2,8 | 2,36 | 2 | 1,7 | 1,4 | 1,18 | 1 | 0,85 | 0,71 | 0,6 | 0,5 | 0,42 | 0,35 | 0,3 | 0,18 | 0,12 | 0,07 |

| Screen Size (inches) |

0,111 | 0,0937 | 0,0787 | 0,0661 | 0,0555 | 0,0469 | 0,0394 | 0,0331 | 0,0278 | 0,0234 | 0,0197 | 0,0165 | 0,0139 | 0,0117 | 0,007 | 0,0049 | 0,0029 |

Guide to Steel Grit Sizes and Applications

Guide to Steel Grit Sizes and Applications

A Simple Guide for Effective Surface Preparation

Understanding the different sizes and applications of steel grit is important for achieving the best results in cleaning and surface preparation, FAST. This guide provides clear and concise information on various steel grit sizes, their general properties, and their specific uses. Whether you’re removing rust, cleaning surfaces, or preparing materials for coating, this quick guide will help you choose the right steel grit for the job. Use this resource to ensure your maintenance tasks are performed efficiently and effectively.

| Grit Size | Approx. Size of Abrasive | Grit Finish Produced | General Applications |

| G-120 | 0.125 mm / 005″ | Very light etch-Matte or satin finish |

|

| G-80 G-50 G-40 |

0.30 mm / 0.012″ to 0.60 mm / 0.025″ |

Medium etch |

|

| G-25 | 0.71 mm / 0.03″ | Sharp etch |

|

| G-18 G-16 G-14 |

1 mm / 0.04″ to 1.7 mm / 0.065″ |

Deep etch, rough |

|

| G-12 | 1.85 mm / 0.07″ | Very rough |

|

W Abrasives grit angular products are available in various degrees of hardness, which will impact the finish and applications. Please contact your W Abrasives representative for support and advice.

Discover the perfect abrasive for your needs by using our “Find the Right Product” tool, designed to match your specific application, equipment, and parts.

Frequently Asked Questions (FAQ) about steel grit

Frequently Asked Questions (FAQ) about steel grit

Key inquiries in steel grit abrasives

Steel grit is utilized in the industrial sector for the preparation of metallic surfaces prior to the application of coatings of in desanding and descaling applications in foundries and forging. It is designed to remove existing coatings, rust, sand, scale and other contaminants, creating a clean, rough surface texture. This process enhances the adhesion of subsequent coatings, ensuring their longevity and effectiveness.

Steel grit comes in various hardness levels to suit different applications. General hardness ranges from 40 to 65 HRc, 40-51 HRC is for softer applications like removing softer coatings without damaging the underlying surface, while harder steel grit, up to a minimum of 60 HRC, is preferred for more aggressive surface preparation tasks, such as removing tougher coatings or creating a profile on harder materials.

Steel grit is categorized into different grades based on hardness. It includes GP (General Purpose) for softer grit, GB and GL (greater hardness ranges) for a medium , and GH for the hardest grit. Each greade servers different needs and are suitable for specific applications.

The main difference lies in shape and application. Steel shot is spherical and ideal for peening or removing light scale and sand, while steel grit, with its angular shape, is more effective for surface preparation and cleaning application, where it can etch the metal surface to improve coating adhesion.

The softer GP range is perfect for shot blast turbines aimed at preserving delicate surfaces. In contrast, harder steel grit like GB is somewhat more aggressive, making it suitable for typical surface preparation. GL, being harder, is best suited for descaling, while the hardest range of steel grit, GH, proves effective in rough and heavy surface treatment processes.

The chemical composition of steel grit typically contains carbon (C), silicon (Si), and manganese (Mn). These elements are controlled three times for each production batch to meet strict internal quality standards, ISO standards, and industry norms. The high carbon content ensures hardness and durability, whereas manganese and silicon contribute to the grit’s strength and abrasive properties. Sulfur (S) and phosphorus (P) levels are kept to a minimum to prevent brittleness in the steel.

Our steel grit comes in a variety of sizes, and sizing is determined by a numbering system ranging from G12 (larger, coarser particles) to G120 (smaller, finer particles). This range allows for selection based on the desired surface finish and the specific requirements of the surface preparation task, from aggressive cleaning and profiling to more delicate operations. Typical sizes include, from largest to smallest: G12, G14, G16, G18, G25, G32, G40, G50, G80, G120.

The numbers in steel grit sizes, such as G25, G40, G80, or G120, correspond to the grit’s mesh size or the number of holes per linear inch in the screen through which the grit is sized.

Our steel grit adheres to various industry standards, such as WAE, SAE J444, SAEJ445, SAE J1993, ASTM D4940, and SSPC-AB3, ensuring quality and reliability.

The minimal chloride and salt levels, below 50 μS/cm, reduce the risk of surface contamination, ensuring extended life for coatings and paints.