Dust Tape Kit

Analyze and measure the quantity and size of dust particles on peened or shotblasted components:

You must pay very close attention to metallic surfaces during cleaning to ensure they are spotless before being painted or treated. The Dust Tape Testing Kit allows you to detect remaining particles that could prevent proper corrosion protection.

This ISO 8502 standard-based tool can provide a precise estimate of metallic dust presence rates. W Care experts can help you find and use solutions to eliminate these particles.

Benefits

Benefits

Dust tape kit

Why check for dust on peened steel parts?

The onset of rust is not just due to bad paint quality or to rough surfaces that haven’t been properly preventively treated. Dust particles, some of which can be rather large (often > 100 µm), may trigger corrosion.

The Dust Tape Testing Kit helps identify these particles and provides precious information about the peening process, as well as ancillary issues such as cross-contamination due to neighboring activities.

Characteristics

Characteristics

Dust tape kit

How to use the Dust Tape Kit

The ISO 8501-1 standard classifies materials into four categories: A, B, C and D, according to their visible oxidation prior to peening. Classes A, B and C are analyzed using the Dust Tape Testing Kit after the peening process. However, class D is so corroded that this tool’s usefulness remains limited.

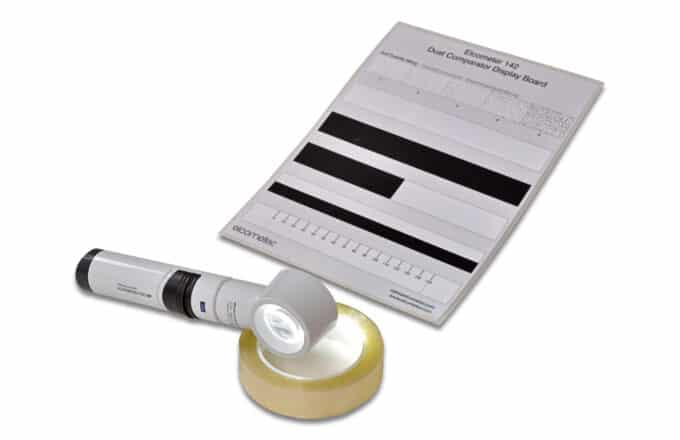

The Dust Tape Testing Kit uses a special adhesive called Elcometer 142, which our W Care experts apply to the analyzed surface. Then, the Elcometer 145 or Dust Tape Roller is used to apply three series of constant 4 to 5 kg force onto the adhesive, thanks to the tool’s regular calibration.

Dust analysis technique

Dust analysis technique

Dust tape kit

Evaluation of dust quanity and size particules

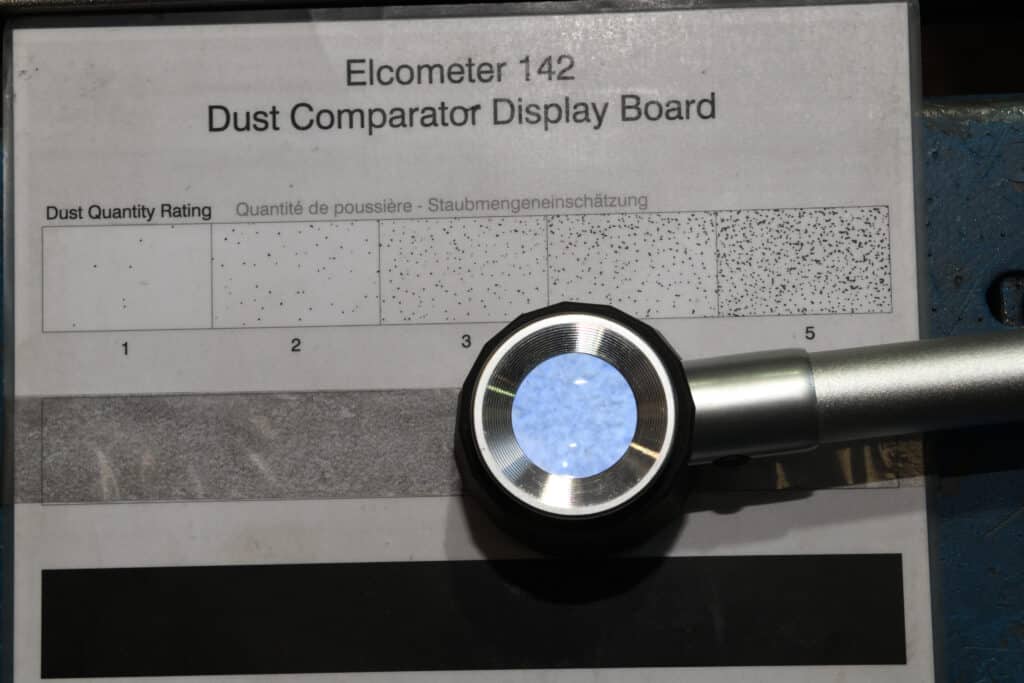

After removing the adhesive tape from the metal structure, it is affixed to an unused Dust Tape Testing Kit sheet. The sheets include light and dark strips for better particle observation. A x10 magnifying glass is used to study the samples.

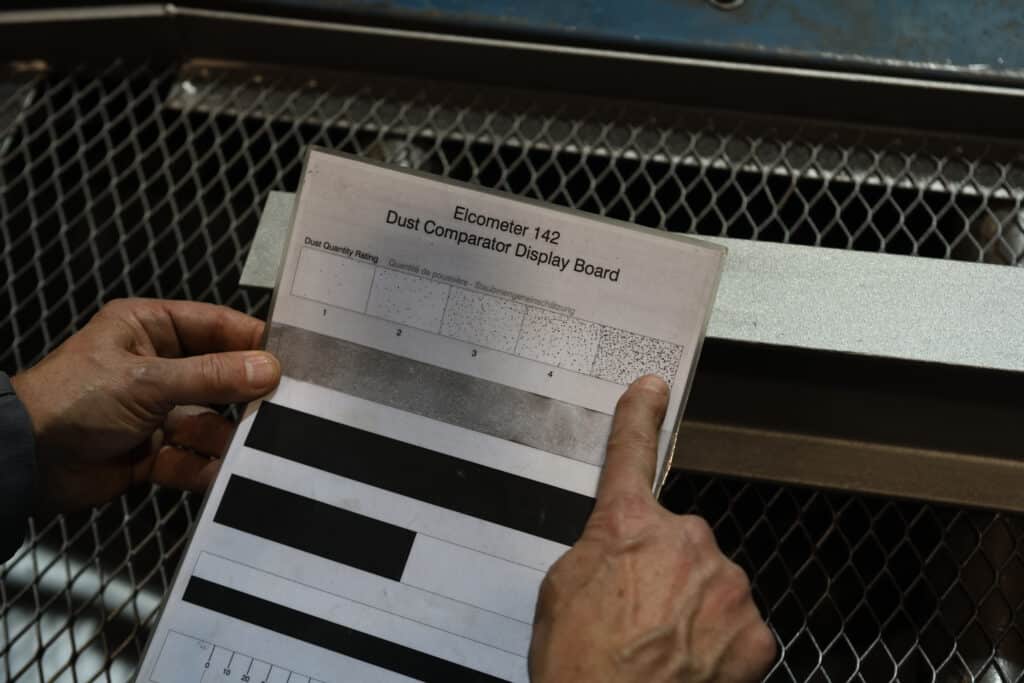

The first step consists of evaluating the amount of dust retained by the adhesive tape as compared to the reference quantity indicated by the Dust Tape Testing Kit.

This measurement is categorized into five classes, with the first having a low number of particles and the fifth having a very high number. Class grades are attributed according to the closest comparable measurement.

We then assess average particle size. A x10 magnifying glass is used to compare it with the six other reference classes. Class 0 denotes invisible particles, while class 5 includes particle sizes larger than 2.5 mm. The corresponding number is recorded on our model sheet.

Measures to implement based on results

Classes 3, 4 and 5 may require promptly applied measures. These measures may include tuning blast chamber suction, using more suitable shot, monitoring hotspots, or even separating the blasting workshop from the rest of the factory to reduce dust and its effects.