Contamination of Metal Surfaces: What are the risks?

Surface treatments and coatings are essential methods for enhancing the functional properties of metals, particularly their resistance to oxidation and corrosion, fatigue performance in all forms (mechanical, thermal, surface), electrical conductivity, friction and wear resistance, thermal insulation, and even aspects like color and appearance, biocompatibility, or adhesion to other material classes such as ceramics or polymers.

In essence, to achieve optimal and long-lasting strength, it is crucial to subject the initial surface to surface preparation operations, such as shot blasting. This process can be performed using abrasive projection with compressed air or in turbine machines. In the majority of cases, when aiming to optimize the properties of a material, whether metallic or non-metallic, surface phenomena play a decisive role. When facing challenges in improving strength, safety, environmental impact, and cost-effectiveness of installations, it is essential to analyze the risks associated with surface contamination, identify various causes, and propose suitable technical solutions.

Potential risks of surface contamination

If shot blasting is an industrial process widely used to prepare, maintain, and clean the surfaces of various materials by propelling abrasives, it is essential to address potential problem sources to achieve its optimal efficiency. Among the risks, we can mention:

Poor coating adhesion and contamination by cutting oils

Indeed, before undergoing the surface preparation step through shot blasting, the parts to be treated must be free from any traces of oil. Although the oil may have minimal interference during the shot blasting process, the shot will not be able to remove it completely. As a result, the surface will be clean from rust, scale, or other hard substances but will be contaminated by a greasy film, which will adversely affect the proper adhesion of the subsequent protective coating.

Hence, there are risks of very poor coating adhesion. Additionally, even if not all parts are initially contaminated with oil, the oil can transfer to the shot, which remains in the projection system for a considerable time, subsequently contaminating parts that were initially free from oil.

However, several methods can eradicate this oil: manual cleaning or using washers before shot blasting, which function preventively. Also, certain mineral-based powder products can absorb surface grease during shot blasting, acting reactively. Additionally, these products can be used in a shot blaster to cure contamination if the shot becomes polluted, providing a curative approach.

Premature coating failure

This is one of the most severe consequences of inadequate surface preparation before coating. However, the causes can be multiple:

- Residual oil on the parts, as mentioned earlier.

- Presence of soluble salts, as we will see.

- Excessive scale or rust residues if the shot blasting operation failed to achieve the desired cleaning objective.

- Improper surface profile that does not meet the coating manufacturer’s recommendations

Increased risk of corrosion

The presence of soluble salts (mainly chlorides and sulfates) at the steel/paint interface is known to have a detrimental effect on the integrity of most paint systems. The performance of protective coatings applied on steel is significantly influenced by the surface condition immediately before coating. Thus, hydrosoluble contaminants initiate and accelerate corrosion, promoting osmotic blistering and under-film corrosion.

While it is evident that the primary source of salt contamination is mainly due to the immediate environment of the shot blaster (proximity to the sea, humidity levels, ambient temperature, and waiting time of parts between shot blasting and coating), it is recommended to use shot with a very low level of soluble salts to avoid any possible contamination of substrates and surfaces.

Increased equipment wear and the risk of dusting the already cleaned surface

If the shot blasting operation is poorly controlled, dust and residues from rust, scale, and even worn-out shot that has become too fine, will remain in the shot blaster, causing premature wear due to abrasion.

Worn-out equipment, failing to remove the residues from the operational mix, will recontaminate surfaces during the propulsion of these particles.

What are the causes of surface contamination?

For every problem, there is a reason. By identifying it, it becomes easier to provide a durable and effective technical solution. Among the reasons that can lead to surface contamination are stagnant dirt and dust even after shot blasting, poor-quality cleaning at all stages of the process, and incorrect machine parameters. The causes can be multiple, but it is worth noting that the main reason for surface contamination often lies in a misunderstanding and improper execution of the shot blasting operation.

Here is an overview of the main causes leading to underperformance and lack of quality:

- Presence of oil, grease, or other contaminants on the surface before shot blasting.

- Use of contaminated or incompatible abrasives.

- Insufficient pre-cleaning of the surface.

- Inadequate dust removal during shot blasting.

- Static electricity caused by the shot blasting equipment (attracting dust and particle agglomeration).

- Inadequate cleaning after shot blasting.

- Reusing worn-out or degraded abrasives.

- Lack of proper maintenance of the shot blasting equipment.

- Operator errors during the shot blasting process.

How to reduce the risks of surface contamination?

Surface preparation requires careful attention to achieve optimal effectiveness. It is the first step in treating a metal surface before applying a coating. To achieve this, tailored technical solutions are necessary for each situation.

Properly preparing a surface involves cleaning it from all contaminants such as oils, greases, rust, scale, and slag. Additionally, it is essential to create a suitable profile on which paint and other overlay materials can adhere properly.

Here are the key points of focus and potential solutions to ensure consistent and reliable coating quality…

Pre-cleaning of the parts

An essential and often overlooked or neglected step that helps remove oils, greases, and other contaminants.

A recent solution on the market is the addition of PantaTec. With the PantaTec method, simply adding an additive separates troublesome oils and greases from the metal surfaces, bonds with them, and eliminates them from the process. As a result, even greasy metal surfa

ces can be degreased and shot blasted in a single step, seamlessly, and can even be coated directly.

Selecting a suitable abrasive

For every surface and purpose, a recommended type of abrasive exists. However, to ensure the lowest contamination of your surfaces:

- Use stainless steel shot to avoid ferrous contamination for sensitive surfaces.

- Opt for an abrasive that generates fewer dust or contaminants (e.g., metallic shot).

- Choose materials and shot with low salt content.

- Prioritize premium solutions.

Surface cleanliness control

ISO 8001 and SSPC/NACE standards allow for analyzing the residual cleanliness of rust and scale after shot blasting by comparing them with standardized texts or visuals.

For more precise and objective cleanliness measurements, Winoa has developed WA Clean, a patented ISO technology ideal for evaluating and verifying the cleanliness of a shot-blasted surface in accordance with international standards, independently of any human interpretation. It reads, quantifies, and archives thedegree of surface cleanliness you have achieved.

Dust control on surfaces

To test the dusting of shot-blasted steel surfaces, the evaluation and reference standard is ISO 8502-3:2017. Also known as the “Replica Tape Method,” this ISO standard provides a precise procedure and includes a reference description and a photo with 6 dusting ratings for comparison.

Eliminate static electricity

Static electricity is a common cause of dust on surfaces. Simply ensure that there is no static electricity in the shot blasting system by grounding the equipment and using antistatic supply hoses.

Check for abrasive embedment

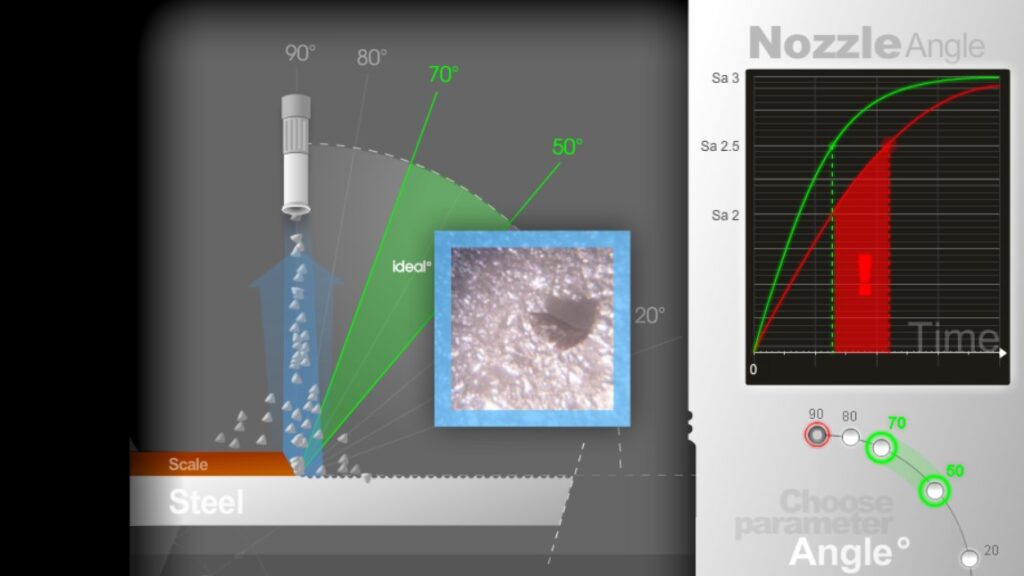

This phenomenon occurs occasionally during high-speed compressed air shot blasting, particularly with very hard abrasives and when the nozzle angle is incorrect (e.g., 90° instead of the ideal 50° to 70°).

Besides being less effective in terms of cleaning speed, blasting at a right angle to the surface increases the risk of abrasive embedment in the cleaned surface. It is essential to ensure proper scraping of the surface to remove these embedded grains.

Operator Training

Reducing risks also involves being proactive. By training your operators in the appropriate techniques and addressing the challenges they may encounter, you ensure a serene, efficient, and safe production.

For the treatment of your metal surfaces, trust in the expertise of Winoa.

In order to prepare the surfaces of tomorrow, Winoa offers shot blasting solutions comprising of abrasives, a diverse range of services, and technologies to optimize industrial processes. Your best solution is to rely on the expertise of W Care’s technical teams.

Our experts begin with a simple diagnosis of the existing process on your site and guide you to optimize it while reducing your costs. This expertise allows us to bring overall improvements, from the choice and use of abrasives to shot blasting operations and equipment.