Interview with Falko Schmidt by MFN: Beyond Traditional Abrasives : Cutting-Edge Technologies Transform Surface Preparation

An Interview with Falko Schmidt by MFN : Reinventing Surface Preparation with Innovation, Sustainability and Customer-Centric Solutions

Metal Finishing News (MFN) recently sat down with Falko Schmidt, CEO of the newly created Specialty Abrasives & Peening Solutions Division at Winoa. This new division plays a pivotal role in Winoa’s ambitious “Turbo 2030” strategy, aiming to drive innovation and growth in high-performance blasting and peening technologies.

In this exclusive interview, Falko Schmidt shares his vision for the future of surface preparation, the strategic importance of specialty abrasives, and how Winoa is leading the way through sustainability, partnerships, and advanced R&D. From introducing HD cut wire production in Europe to leveraging AI and expanding customer services, discover how Winoa continues to push industry boundaries and shape the future of peening.

Strategy & Role of the Division

At the heart of Winoa’s Turbo 2030 strategy is a clear ambition: to strengthen its core business while accelerating growth in specialty abrasives and peening solutions. Falko Schmidt describes the newly formed division as the “engine” of this strategy, built to serve global clients with high-value, tailor-made solutions.

Unlike traditional steel abrasives, this division focuses on advanced products like STELUX™ stainless steel shot and HD cut wire, aiming to serve industries with increasingly complex surface preparation needs. Backed by dedicated global resources and partnerships, notably with Toyo Seiko and Frohn, the division is positioned to drive innovation and responsiveness on a worldwide scale.

Market Strategy & Growth Plans

In terms of market reach, Winoa sees opportunity across the globe. Falko highlights mature regions like Europe and North America as key markets for advanced peening and surface finishing, while also pointing to India, the Middle East, and Japan as emerging growth hubs.

Industry-wide trends, especially the shift to lightweight materials in aerospace, automotive, and energy, are creating a demand for more sophisticated media. Winoa is strategically responding by aligning its specialty offerings to help customers increase component durability without adding weight.

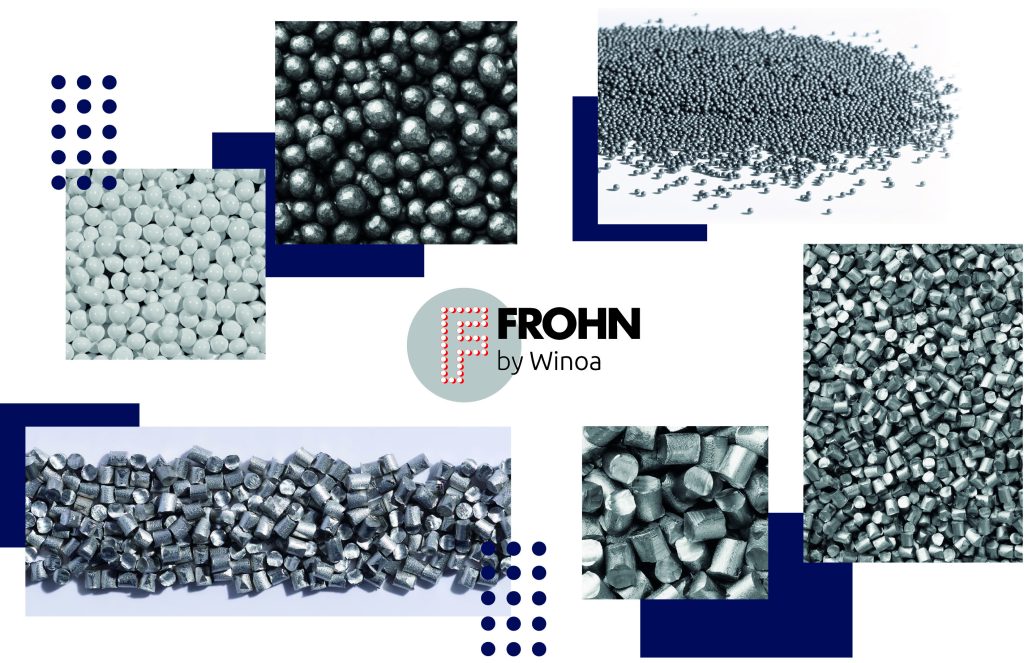

(Image: HD steel cut wire shot for long-lasting peening applications)

To meet global demand while maintaining quality, Winoa is investing in AI-driven process control, local partnerships, and expanded production capabilities. This ensures both performance consistency and customer proximity, two pillars of the company’s global growth approach.

Innovation & Technology

Falko emphasizes that innovation begins with understanding customer challenges. Whether it’s maximizing fatigue life or enhancing the surface integrity of advanced alloys, Winoa is committed to pushing the limits of what’s possible in peening and blasting.

Key developments include the launch of HD cut wire production in Europe, which will improve responsiveness and reduce lead times, and continuous optimization of STELUX™ stainless abrasives to further reduce process costs while maintaining exceptional recyclability and durability.

(Image: Frohn, now part of Winoa, expands our specialized cut wire capabilities)

Additionally, the synergy with Frohn and Toyo Seiko is driving forward the development of hybrid solutions, combining global reach, technical excellence, and local manufacturing expertise to better serve complex industrial needs.

Want more?

The full interview also covers additional major topics, including:

- Sustainability & Industry Trends

- Customer Impact & Service Improvements

- Vision for the Future

Falko shares insights on how Winoa is cutting emissions, optimizing operations with AI, and redefining its service model for global customers seeking more than just media, they want full blasting and peening solutions.

Discover the full interview with Falko Schmidt, click here to read it