Field expertise that drives results: Interview with Michal Klus, WCare Technical Expert

With locations spread across Central Europe, WCare expert Michal Klus has become a trusted partner for customers in the Czech Republic, Poland, Slovakia, and Romania.

In this interview, he explains how technical expertise on the field creates measurable improvements, strengthens customer relationships, and opens new opportunities for process optimization.

Meet Michal Klus, W Care technical expert

Question: Michal, can you introduce yourself and your role at Winoa CZ?

Michal Klus: I’m Michal Klus and I joined Winoa in August 2022. I work as a W Care Technical Expert for the Czech Republic and Poland, but my support extends further — I regularly visit customers in Slovakia and occasionally in Romania. My mission is simple: help customers improve efficiency, solve technical problems, and get the most out of their blasting operations.

Detecting inefficiencies early

A key part of the job

Question: From your experience, what are the most common issues you detect on customer sites?

Michal Klus: Efficiency issues — without a doubt. But “efficiency” can mean different things depending on the industry. In foundries, it often means removing sand as quickly as possible, so the focus is on selecting high-quality blasting media. In surface preparation, the priority is achieving consistent roughness, and this is where Hot Spot Checks become essential.

Hot Spot analysis is an extremely powerful tool. By understanding the projection angle and energy of each wheel, we can improve performance dramatically. Last month, after only a small Hot Spot adjustment, we reduced a customer’s blasting cycle from 10 minutes down to 4 minutes. That’s the kind of impact expertise can bring.

Discover hot spot analysis in details

Question: How do customers react when small adjustments lead to big improvements?

Michal Klus: In most cases, improvements are in the range of 10–15%, which is already significant. When results are even stronger, customers are usually surprised by how much efficiency was hidden in the machine settings.

However, technical adjustments often require follow-up discussions with the customer’s technologist or production team, so the full improvement sometimes takes time to implement. But once they see the results, the reaction is always very positive.

Technical Expertise with a human touch

Question: How do you balance technical precision with the human side of your work — listening, explaining, and training?

Michal Klus: For regular customers, the communication is easy — they already understand the basics, and I can focus directly on machine inspection and fine-tuning. When I find something, I always take the time to show it on site and explain the root cause.

With new customers or operators, training becomes essential. I prefer to work side by side with them, showing every step of the inspection: what to check, how the machine behaves, and what they can monitor themselves. It builds trust and accelerates learning.

Question: What do you enjoy the most in your daily work?

Michal Klus:When we identify an issue and the customer can react immediately — replacing a part, adjusting a setting, correcting a parameter. You can see the improvement right away, and that’s extremely rewarding.

Digital Tools: Enhancing, Not Replacing, Field Expertise

Question: How is digitalization supporting your work with customers?

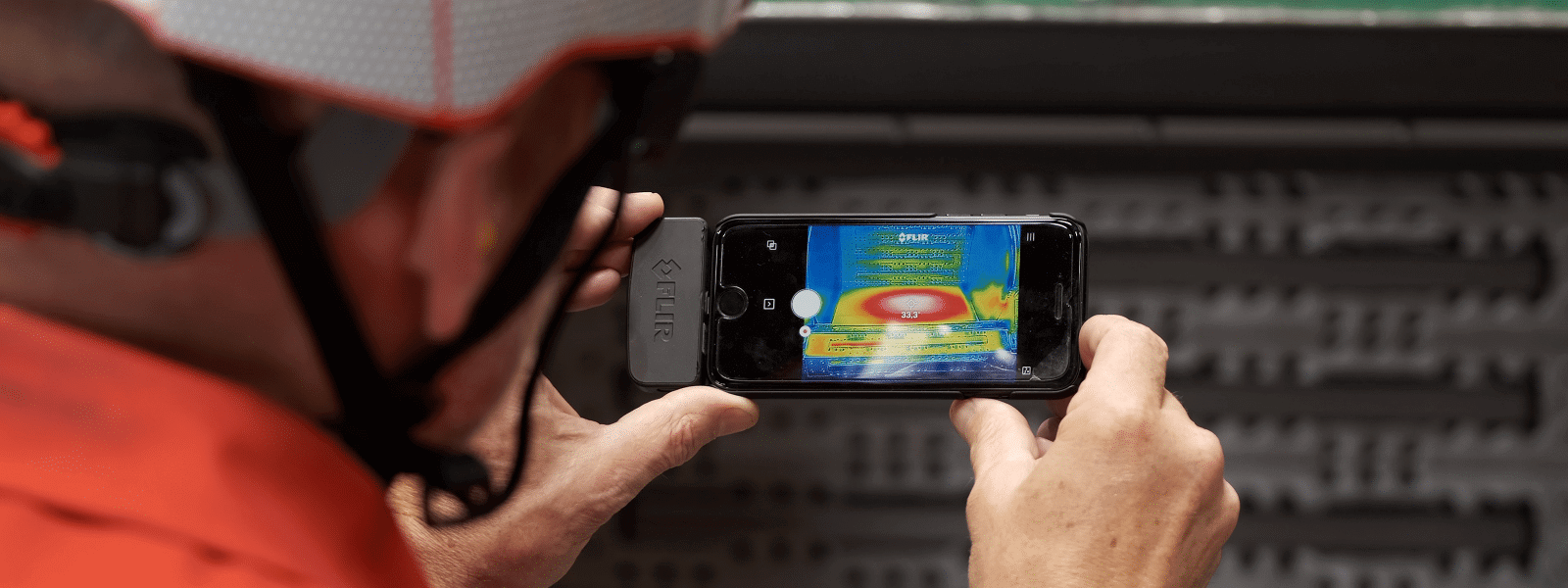

Michal Klus: Digital tools are becoming increasingly important. I occasionally test the AR helmet — it’s a great showcase of what the future may bring. But for daily field work, I rely more on practical tools such as my iPhone or iPad, mainly for taking pictures, documenting findings, and using the W App.

WA Clean has become a standard for our job. It’s a simple but extremely effective quality control tool, and customers immediately understand the value.

The value of a W Care Expert: insight, precision, partnership

Michal’s approach illustrates what makes W Care so impactful:

✔ early detection of inefficiencies

✔ hands-on machine optimization

✔ practical on-site training

✔ expert use of diagnostic tools

✔ strong customer relationships built on trust and results

We sincerely thank Michal for his commitment, his precisions, and his strong expertise at the benefice of our customers across Europe.

Don’t hesitate to contact us for more information about our services or to request support

Our Tech Center in Czech Republic

A Hub for Innovation, Training, and Eco-Responsible Blasting Solutions

At the heart of Europe, our Technical and Service Center in the Czech Republic is a crucial pillar of our growth strategy. Located in Zlatniky, near Prague, this center is a hub of innovation and customer service, dedicated to providing bespoke shot blasting solutions and high-quality peening services.