Identify hidden shot blasting costs without disrupting production

Why this matters ?

Most plants track the price per kg of abrasives. But real blasting costs rarely appear on the invoice.

They usually hide in:

- slowly increasing abrasive consumption,

- energy-intensive settings that still “work,”

- recovery losses,

- downtime, rejects, and rework.

Because these effects are gradual, they often remain invisible until margin pressure increases. That’s why Total Cost of Operation (TCO) matters.

What is an efficiency audit TCO ?

What it is

A structured, measurement-first review that helps you understand what your blasting process really costs per part.

- Focused on data, not assumptions

- Based on your current setup

- Designed to support decision-making

What it is NOT

- Not a consultancy project

- Not a process reset

- Not a supplier change

What we measure

To build a meaningful TCO baseline, the audit focuses on 4 key cost drivers:

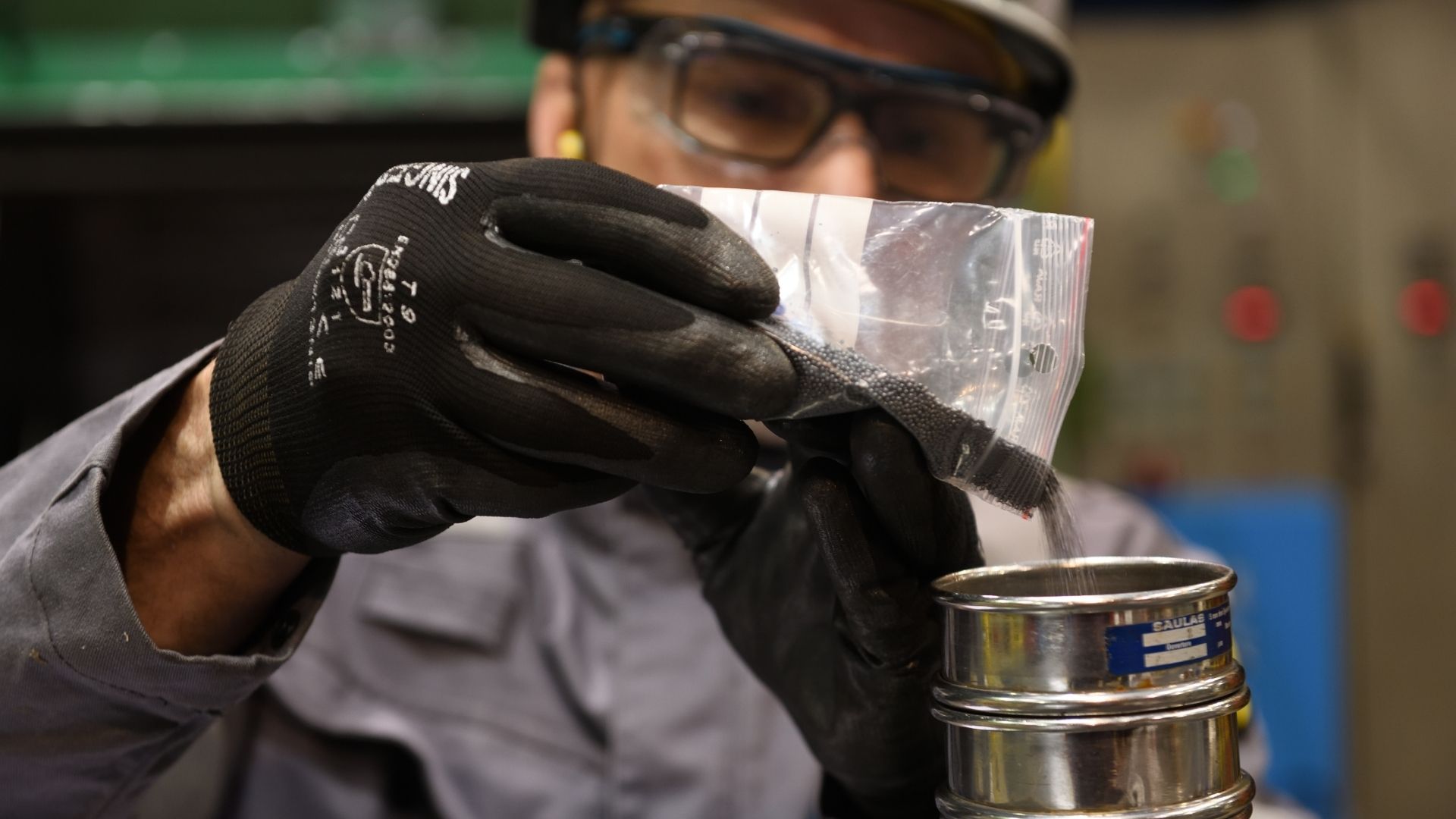

- Abrasive consumption : kg per part or kg per ton

- Energy per output : kWh per part or per ton

- Downtime linked to blasting : maintenance, adjustments, instability

- Rejects and rework : related to surface preparation variability

These indicators are measurable, comparable, and directly linked to margin.

How the audit works

- Fill in the form :

Share minimal information about your blasting process. - Receive a practical guide tailored to your process:

wheel blasting, or air blasting. These guides help stabilize performance and prevent cost drift. - We contact you to schedule a free audit

A short, remote-first discussion to- establish a TCO baseline,

- identify main cost levers,

- define together how to reduce the cost of your blasting process.