Winoa-2Effe shot peening center in Czech Republic

Shot peening and XRD analysis in practice

Explore new possibilities of the Tech Center and find out how to measure residual stress

Do you know exactly what residual stress your components have after blasting? An incorrect process can shorten the part’s lifespan. Come and see how to measure it exactly.

Leading the Way in Peening

Who we are

Winoa-2Effe Private Limited is a joint-venture between Winoa, world leader of steel shot market, and 2Effe Engineering, the reference of shot-peening services in Europe.

- You are looking to out-source shot-peening process?

- You need to assess residual stress through X-ray diffraction?

- You want to grow your team skills and knowledge on the shot-peening process?

We’ve got your back through our Technical Center facility with brand-new equipment dedicated to shot-peening excellence in Zlatníky- Hodkovice, near Prague, in Czech Republic.

What you can expect?

Know-how

How to correctly set up the shot peening process for maximum fatigue life of parts.

Technology in action

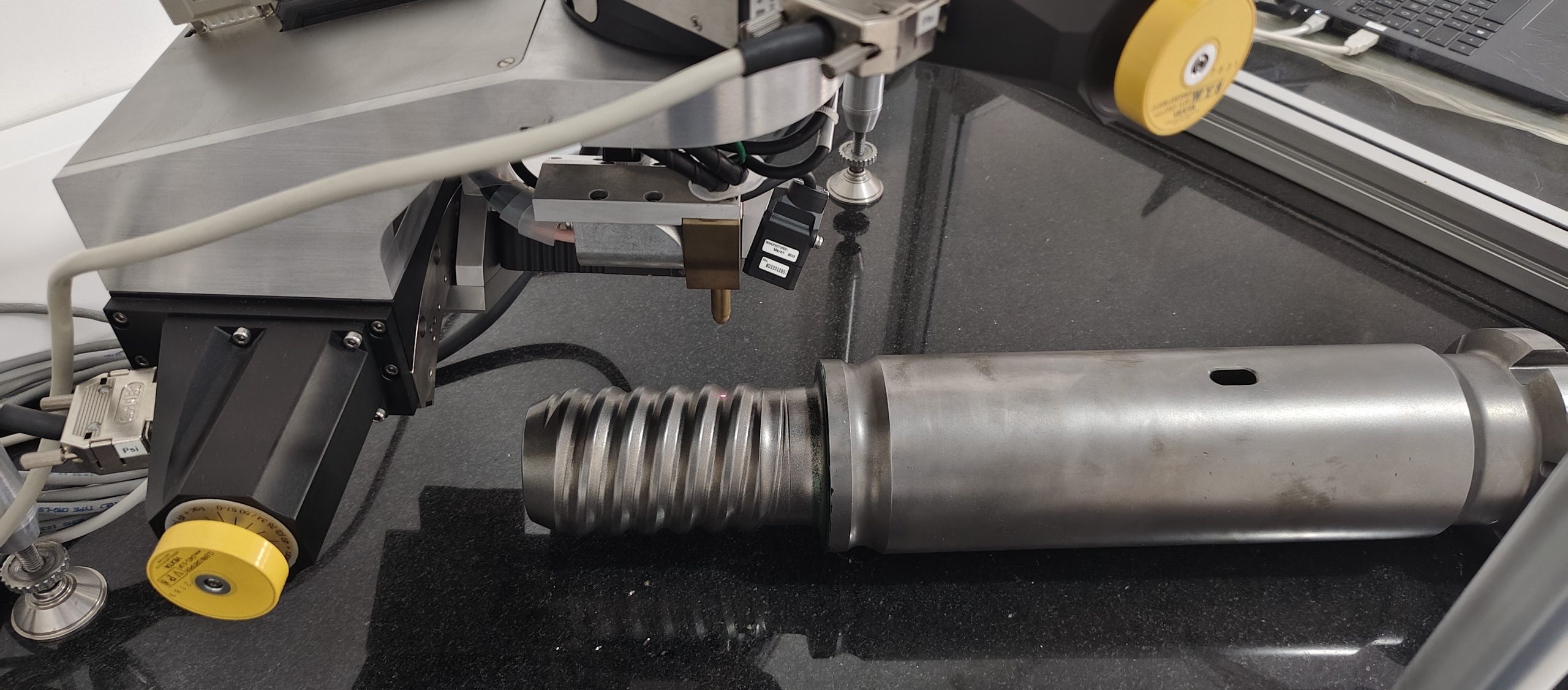

Live demonstration of X-ray diffraction (measuring stress that is not visible to the naked eye).

Consultation

Consultation of your specific projects with Winoa experts.

Program

- 08:30 – 09:00 | Welcome, morning coffee, and refreshments

- 09:00 – 10:30 | Introduction of WINOA and 2Effe: Our services, tools, and technical expertise in practice.

- 10:30 – 11:00 | Coffee break

- 11:00 – 12:30 | Tech Center Tour: Demonstration of machinery, processes, and measurement methodology.

- 12:30 – 13:30 | Networking lunch

- 13:30 – 15:00 | Practical XRD demonstration: Real-time demonstration of X-ray diffraction.

- 15:00 – 16:00 | Open discussion: Consultations and testing XRD measurements of your brought-in parts.

When & Where?

Kdy: 25th of March, from 9 AM to 4 PM

Kde: Tech Centrum Zlatníky-Hodkovice (Google mapy, Mapy.com)

Our comprehensive range of services

Shot peen & finishing services

Peening

X-Rays

Consulting

Training

At Winoa-2Effe, we pride ourselves on offering specialized shot peening solutions tailored to the unique needs of the aerospace, automotive, and power generation industries. Our state-of-the-art technology and expert approach ensure optimal fatigue performance and surface enhancement for a variety of components. Discover our dedicated services and how they can transform your project:

Focus on residual Stress Analysis

Our center uses X-ray diffraction (XRD) — a precise, non-destructive method to measure residual surface stresses. This verification supports process qualification, component design, and parameter optimization, offered as a standalone service or alongside shot peening.

At Winoa-2Effe, we apply our shot peening expertise to a wide spectrum of industrial components, enhancing durability and performance. From automotive to aerospace, discover how our treatments fortify and extend the life of critical parts in various sectors.

A Hub for Innovation, Training, and Eco-Responsible Blasting Solutions

Winoa tech center

At the heart of Europe, our Technical and Service Center in the Czech Republic is a crucial pillar of our growth strategy. Located in Zlatniky, near Prague, this center is a hub of innovation and customer service, dedicated to providing bespoke shot blasting solutions and high-quality peening services.

Any questions about shot peening availabilities or facility ?

contact us today

"*" indicates required fields

The Winoa Tech Center Central Europe features:

Industrial blast machines

Our technical center is equipped to provide custom shot blasting solutions. Whether you need stainless steel abrasive blasting or a peening service, we have the equipment and expertise to meet your specific needs.

A spacious training room, accommodating up to 20 people.

An extensive range of abrasives for trials, including Premium steel shot and grit media, stainless-steel abrasives, and various metallic cut wires.

Winoa Shot Peening & Tech Center:

Průmyslová 137

25241 Zlatníky- Hodkovice

Czech Republic

Phones: +420 603 181 041

Emails: techcenter.cz@winoa.com