Reinventing surface preparation: how the 3:1 approach unlocks performance gains

In today’s industrial world, every step in production is a chance to improve. Yet surface preparation – especially shot blasting in foundries – is often seen as a secondary task. That’s a mistake.

The hidden costs of inefficient shot blasting

Shot blasting plays a crucial role in product quality, coating adhesion, operating costs, and overall process stability. It’s far more than a support function: it’s a key driver of operational performance.

And, modern shot blasting operations are often under pressure to maintain high quality and keep costs in check, all while ensuring production continuity. On top of that, they face growing challenges such as labor shortages and increasing demands for sustainability.

Common issues in shot blasting workshops include:

- Drifting machine settings, often due to wear or poor setup (e.g. misaligned turbines, open control cages)

- Degraded abrasive mix, with excess fines or broken particles lowering efficiency and increasing cycle time

- Unplanned equipment failures, disrupting the production line

- Excessive use of energy or abrasives, due to worn or misconfigured machines

These problems create hidden costs: reduced productivity, higher scrap rates, and blown budgets. That’s where Winoa’s 3:1 integrated approach comes in.

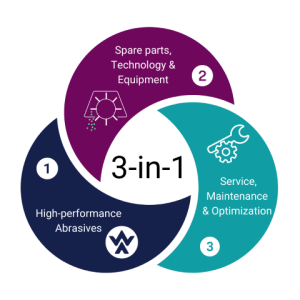

The 3:1 model: combining abrasives, parts, and services for optimized blasting

Winoa delivers a structured and proven solution based on three essential pillars: abrasives, parts, and technical services.

- High-performance abrasives

W Abrasives® products are designed for durability, consistent blasting performance, and improved energy efficiency. Their stable shape ensures uniform blasting without excessive wear or energy use. - Machine parts and maintenance

We provide OEM or compatible parts, like blades, cages, and linings, to keep your equipment performing at its best. Our W Care technical teams also offer on-site repairs, machine adjustments, and preventive maintenance support. - Services and process optimization tools

From full audits to targeted training, we help you find and act on your most profitable improvement areas.

Real-world result: After adjusting abrasive flow, realigning turbines blast patterns, and replacing worn linings, one client achieved +18% blasting efficiency and -10% abrasive usage.

TURBO 2030: smart, sustainable blasting

Winoa’s TURBO 2030 program adds digital intelligence to your process, turning traditional shot blasting into a connected, sustainable operation:

- IoT sensors: Track temperature, productivity, and vibration in real time

- Predictive maintenance: Use data to avoid failures before they happen

- Eco-optimization: Reduce dust, noise, and abrasive waste

This proactive, data-driven model transforms how blasting is managed, improving performance and sustainability.

Measurable impact: cost control and consistent quality

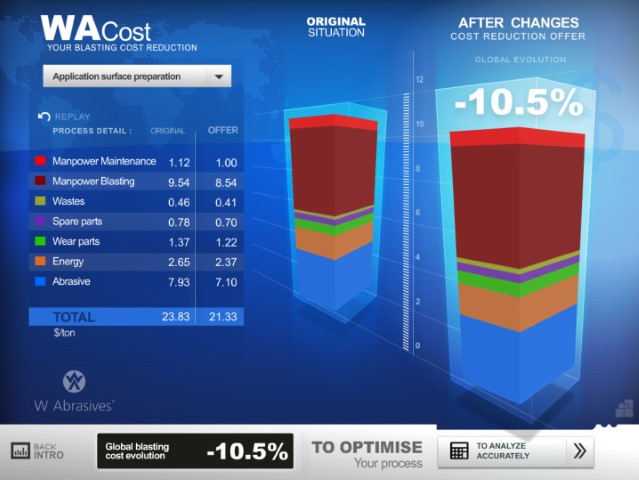

Clients using the 3:1 approach and TURBO 2030 report tangible results:

- Up to 15% lower total blasting costs

- Fewer unexpected stoppages due to better maintenance planning

- Improved surface consistency and fewer quality issues

- Clearer cost visibility with WA Cost™

Conclusion: surface preparation is a strategic priority

Shot blasting should not be treated as a fixed, background process. With our 3:1 approach and TURBO 2030 program, surface preparation becomes a controllable, high-impact lever for performance.

For a technical evaluation of your setup, contact our experts:

Written by:

Iann Bouchard, Eng.

Group Marketing & Communication Director at Winoa

Together, let’s make shot blasting a strategic asset.