The W Abrasives teams approach the customer to propose him a customized solution and allow him blasting costs reduction.

A cast iron foundry customer is producing 800 tons per month of manholes and other miscellaneous parts for civil and road works. They are running a 16 wheel continuous hanger machine which consumes 300 tons per year of S550. Initially, 65% of this volume was supplied by one of our sister company, the rest by a local competition.

The customer had too much re-blasting on some products which considerably increased its costs. Thus he needed a more efficient product to reduce his re-blasting rate, without increasing the maintenance cost.

The Premium product Hybrid Shot, specially designed to reduce overall blasting cost through a combination of high cleaning efficiency and low machine wear has been introduced.

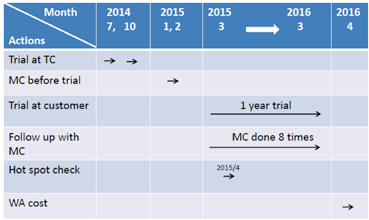

Hybrid Shot introduction through the complete Premium approach: use the concept of the 7 steps :

In addition to the high performances of Hybrid Shot (better efficiency than S550 with limited impact on machine wear), our technical support has allowed to:

Reduce maintenance costs thought:

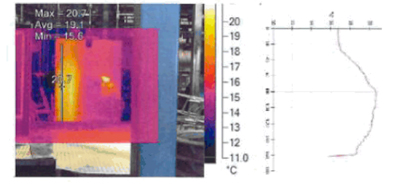

- Hot spot check with WA CAM (innovative technology which allows visual and precise identification of the real position of hot points generated by the turbines, but also visualization of preferential wear zones on the machines)

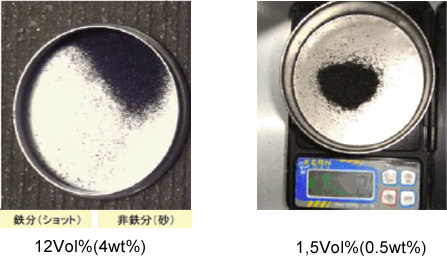

- Reduction of sand content in the operating mix – from 4 wt% to 0.5 wt% – through air separator fine tuning)

Increase efficiency of the machine (hot spot check with thermal camera + adjustment of operating mix size distribution – rejection size decreased from 0.85 mm to 0.6 mm – through air separator fine tuning)

At the end of the trial, this approach allows the following customer benefits:

From then, the customer is working 100% with Winoa.