The Blast Media Recovery System

Blast media system :

What makes blasting with steel media cost effective is that the media can be used several times before it has broken down to the point that it is no longer effectively impacting the parts being cleaned. While new abrasive certainly provides the greatest impact, as it breaks down, it becomes useful in getting into the smaller nooks and crannies of the parts, providing a consistent, overall clean. To do this, it must be recovered so that it can be sent to the wheels again and again until it is small enough to be pushed out by the separator.

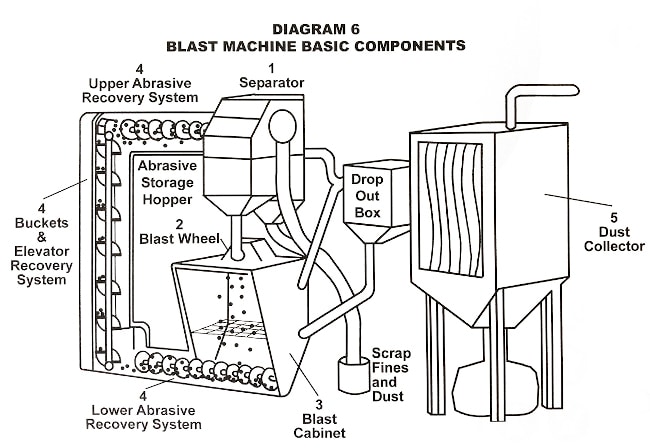

This is where the machine’s recovery system comes into play. The recovery system is a simple concept but requires quite a bit of engineering in the design to keep the flow of abrasive consistent throughout the entire blast machine. Let us look at the basic components of the blast media recovery system in a typical machine and what to check for, maintenance wise. Keep in mind, some machines will have larger or even multiple systems, but the concept is the same across all machines: get the media that was thrown at the parts to be cleaned back up to the wheels to be used again.

1. The Lower Screw

Once the abrasive has been thrown either by wheel or air blast, the media falls to the bottom of the machine. The machine will be designed to funnel the media to one or more augers, known commonly as the lower screw. These augers collect and carry the abrasive from inside the blast cabinet to the next stage of the recovery system, the elevator. The auger system itself consists of the auger screw, the screw shaft, bearings on each end, the motor and gear box. These should be checked monthly for wear and repaired or replaced when bad. Some machines will be designed with shaker conveyor in place of the lower screw. This is usually the case when the blasting will produce a significant amount of tramp metal. The shaker conveyor will have perforations to sift the tramp metal from the abrasive before it enters the rest of the reclaim system.

2. The Elevator

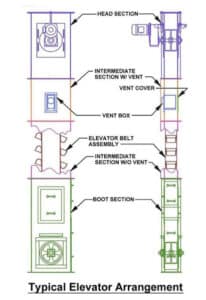

Since gravity plays a key role in the operation of the rest of the operation (the abrasive falls through the separator, then falls to a hopper and finally is fed to the wheels by gravity), the abrasive must get from the bottom of the machine back to the top. This is the elevators role. The elevator is a pulley driven belt which is lined with buckets that scoop up the abrasive from the bottom (elevator boot), carries it up and dumps it into the upper trough where another auger (upper screw) moves it to the separator.

The main components of the elevator will be the elevator housing, belt and buckets, the drive pulley and bearings, the lower pulley and bearings, the shed plate (keeps the abrasive from falling back down the elevator shaft), drive motor and gearbox. Again, these should be checked monthly. Many times, elevator buckets will be worn or missing from the belt or the tracking will be off, and the elevator belt can damage the walls of the elevator housing. Missing elevator buckets can disrupt the abrasive flow through the machine. More on this later.

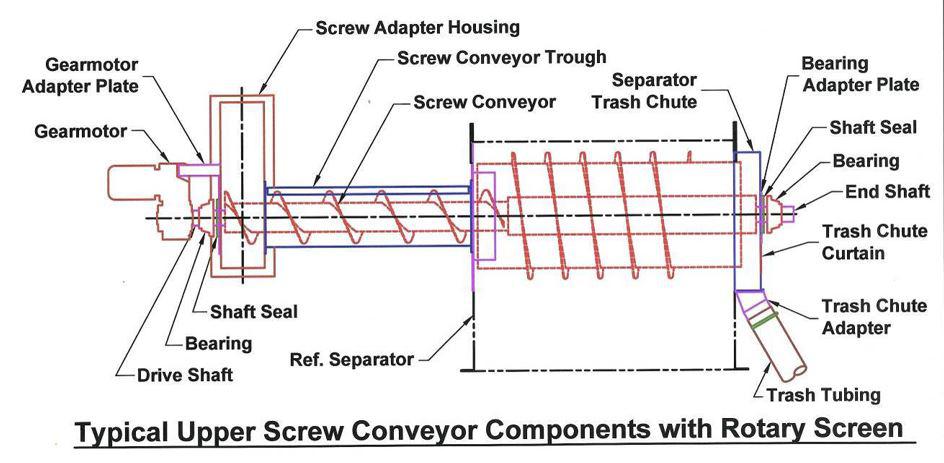

3. Upper Screw

Abrasive Flow

Conclusion

Given all this, you can see how important maintaining the recovery system is to the operation. It is not enough to simply carry abrasive back up to the separator. It must carry the right amount at the correct rate to prevent backups of abrasive and to feed the wheels properly. Too slow and the hopper will eventually empty; too quickly and the hopper may overflow. Missing or worn elevator buckets, worn auger flights and holes in the system can all lead to a disruption of the abrasive flow. With regular maintenance, however, this can be prevented, and your operation will continue to run smoothly.

W Abrasives W Care Technical Team has years of expertise and offer full optimization packages for your machines. Contact your Regional Sales Manager here or distributor today to set up a consultation with one of our Technical Service Providers.

Follow us on LinkedIn and subscribe to our Newsletter: The Blog of Blasting

Written by:

Chris Prouty

Technical Service Advisor, NAO

Chris.Prouty@winoa.com

(682) 300-1885

About blast media recovery systems

Frequently Asked Questions (FAQs)

A blast media recovery system is a technology used in abrasive blasting operations to collect, clean, and recycle abrasive materials after they’ve been used in surface preparation processes. This system enhances efficiency, reduces waste, and lowers operational costs by allowing for the reuse of blasting media.

While many types of abrasive media can be recycled, the efficiency of recycling depends on the type of media, its breakdown rate, and the specific recovery system used. Common recyclable abrasives include steel grit, aluminum oxide, and glass beads. It’s important to consult with system manufacturers to determine the suitability of your chosen media for recycling.

The frequency of abrasive media addition or replacement in a recovery system depends on the type of media, the intensity of blasting operations, and the efficiency of the recovery and cleaning processes. Regular (daily) monitoring of media volumes, condition and performance is essential to determine the appropriate addition quantity or replacement schedule to maintain optimal blasting efficiency.

Some blast media recovery systems are designed to be versatile and be integrated into existing blasting operation systems, whether they’re conducted in enclosed blast rooms or open environments. However, the specific design and capacity of the system need to be tailored to the operational requirements, including the size of the blasting area and the volume of media used. Contact us for more details.