Read the interview with Christophe Bertoncelli, Chief Operations Officer and Head of Industrial Operations at Winoa, conducted by the newspaper Les Affiches de Grenoble et du Dauphiné. In this conversation, he gives us an insight into the fascinating history of Winoa, which over the years has become a world leader in abrasives and surface preparation.

The Origins of Winoa

Question: Can you tell us about the beginnings of Winoa and its evolution to today’s state?

Christophe Bertoncelli: Originally, Winoa was a small company founded in 1961 by the partnership of American Wheelabrator, the holder of metal abrasives or shots manufacturing technology, and the Forges d’Allevard, a steel producer. Over the decades, it has transformed into the industrial giant known today. We have specialized in manufacturing steel abrasives, also known as shots, which are vital for various industrial applications. We have eight production sites worldwide: in France at Cheylas, which is also the headquarters, in Spain, Slovenia, Canada, the United States, Brazil, Japan, and Thailand.

Steel Shot

Question: Can you tell us about steel shots?

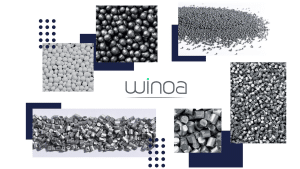

Christophe Bertoncelli: We manufacture steel caviar, small beads from 0.2 to 2 millimeters in diameter, perfectly round or pyramidal, which serve as abrasives when blasted at nearly 300 km/h against the metalwork to be treated. This meticulous process ensures the quality and precision of the shots, which are crucial for achieving optimal results in various industrial applications.

Applications of Steel Shot

Question: What are the major applications that require the use of steel shot?

Christophe Bertoncelli: Our steel shot is used in a multitude of applications. These shots allow us to cater to a variety of needs. They can, for example, clean large foundry parts to remove sand that is clogging them up or rusted beams before they are painted. Steel shot is also essential for surface preparation to create roughness, ensuring paint or coating can easily adhere to the hulls of boats, wind turbine masts, or the insides of pipelines. A third application, mostly intended for the aerospace sector, is surface hardening to prolong the life of components subjected to cyclic fatigue.

These applications are key and essential in industries such as automotive, aerospace, shipbuilding, and many more. We boast over 10,000 clients, including Daimler, Acer Inox, Airbus, and Safran, who can order one to two trucks per week, but also the local blacksmith repainting gates ordering a ton pallet per year, for instance.

Commitment to Circular Economy

Question: Could you tell us about your commitments, notably in the circular economy?

Christophe Bertoncelli: At Winoa, we are deeply committed to the concept of the circular economy. 95% of the steel that enters our Cheylas site is already existing scrap, and when the abrasives, recoverable through magnetism, have made approximately 2,000 rounds in the shot blasting machine and are worn, they are melted down at a scrap dealer’s place to be turned into fresh steel. We recycle up to 96% of the waste involved in our production processes, thereby reducing our environmental impact.

Outlook for Winoa

Question : What are the prospects for Winoa?

Christophe Bertoncelli : We plan to continue our geographical expansion by targeting promising markets such as India. Additionally, we aim to develop our online sales platforms to offer our products and services to a broader audience.

Conclusion

This interview with Christophe Bertoncelli, conducted by Véronique Magnin on April 6, 2024 for Les Affiches de Grenoble et du Dauphiné, provides a deeper understanding of the role of Winoa, the global leader in steel shot blasting and surface preparation. We are committed to innovation, sustainability, environmental consideration, and customer satisfaction. You can find the complete article here.

You can find the complete article here (only French available)