Blasting in Foundries: Towards cost reduction and increased efficiency

In foundries, the efficiency of abrasive blasting is essential to ensure quality, productivity, and profitability. A comprehensive approach encompassing consultation, training, adjustment of parameters, and repair of blasting machines is crucial to maximize savings.

Success in optimizing abrasive blasting heavily relies on understanding diverse needs, which can vary from one client to another, such as :

- improving efficiency,

- reducing maintenance costs,

- enhancing cleaning quality,

- and minimizing abrasive consumption.

The objective is to devise action plans and solutions to achieve specific goals. This approach demands a holistic perspective that considers all aspects of the abrasive blasting process, from selecting the abrasive to operational machine parameters, maintenance, and cost analysis.

Importance of consultation

Technical support and consultation play a paramount role in optimizing abrasive blasting processes. Specialized expertise identifies critical areas for maximizing cost reduction. This approach goes beyond merely considering the initial cost of the abrasive. It involves a thorough analysis of operational efficiency, maintenance costs, energy consumption, and other factors influencing overall performance. With expert consultation, companies receive personalized recommendations and tailor-made solutions that align with their needs and specific challenges, leading to significant optimization of the abrasive blasting process.

Training and machine parameter adjustments

Next in line are training and precise adjustment of machine parameters, which are pivotal levers for optimizing abrasive blasting. Adequate personnel training ensures optimal equipment utilization, contributing to improved efficiency and reduced operational errors.

Simultaneously, adjusting machine parameters is crucial to maximize process efficiency, including :

- the separator (blast curtain),

- projection angle (hot spot),

- abrasive flow rate (amperage),

- types of abrasives, etc.

These adjustments, often based on detailed analysis and technical expertise, can result in significant cost reductions. Targeted interventions, even brief ones, can lead to substantial improvements, with cost reductions reaching up to 15% or more. These gains translate into a notable enhancement of profitability without compromising the quality of the final result.

Tests at the Technical Center

The ability to conduct tests at a specialized technical center is a major asset for abrasive blasting optimization. These centers offer a unique opportunity to experiment with different abrasives, including premium options, without disrupting client production lines. By replicating specific client machine parameters, it is possible to reliably assess the efficiency of various abrasive blasting abrasives directly on the client’s parts. Thus, clients can make informed decisions regarding abrasive choices and process adjustments, based on tangible and measurable results.

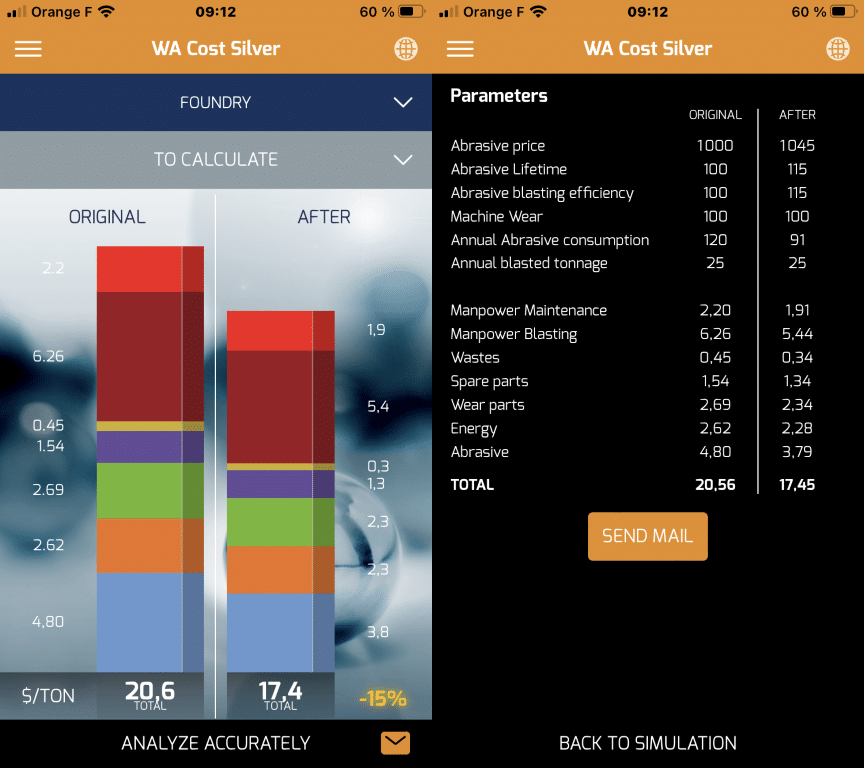

TCO Approach and use of the WA Cost tool

Winoa’s Total Cost of Ownership (TCO) approach to abrasive blasting is a simple and effective method for analyzing costs involved in the abrasive blasting process. This includes costs of parts and maintenance, energy consumption, abrasive cost, and productivity. The WA Cost tool provides a precise and easy-to-understand analysis of costs before and after process optimization. Designed for simplicity, this tool allows clients to input specific operation data, obtaining an overview of costs per produced piece. Consequently, they can clearly measure the impact of interventions and improvements on profitability, facilitating decision-making based on concrete and tangible data.

Maintenance and repair : Keys to optimization

Regular maintenance and targeted repairs are essential to ensure the stability of performance and continuous safety of abrasive blasting equipment. These practices not only prevent costly breakdowns but also optimize operational efficiency, reducing interruptions and maximizing productivity.

Results

The application of the strategies and tools described often yields impressive results in terms of cost reduction. Concrete examples demonstrate significant savings, with abrasive blasting cost reductions regularly exceeding 15%. These savings result from a combination of improvements, ranging from judicious abrasive selection to effective adjustments of machine parameters.

Conclusion

From expert consultation to training, along with machine parameter adjustments and TCO analysis, each type of service offered by Winoa’s W Care teams contributes to improved efficiency and a significant reduction in costs. By adopting these strategies, our clients can not only enhance their profitability but also ensure a consistent and reliable quality of their finished products.

You can find the full article from the Technical Foundry Association: