GET TECHNICAL 2023: Exploration of surface preparation innovation

This meeting provided Winoa with the opportunity to showcase its cutting-edge solutions and address relevant questions from participants through demonstrations and conferences. The central themes that fueled discussions included :

- Circular Economy: How do metallic abrasives actively contribute to the circular economy?

- Product Lifecycle: How does surface preparation influence the lifecycle of products, especially for aluminum frames?

- Process Monitoring: How to ensure consistent quality over time during surface preparation processes?

- Instrument Control: What control instruments are used during and after surface preparation?

Discover in this article the answers to these questions through our expertise and commitments to innovation in the field of surface preparation.

1 Contribution to the Circular Economy

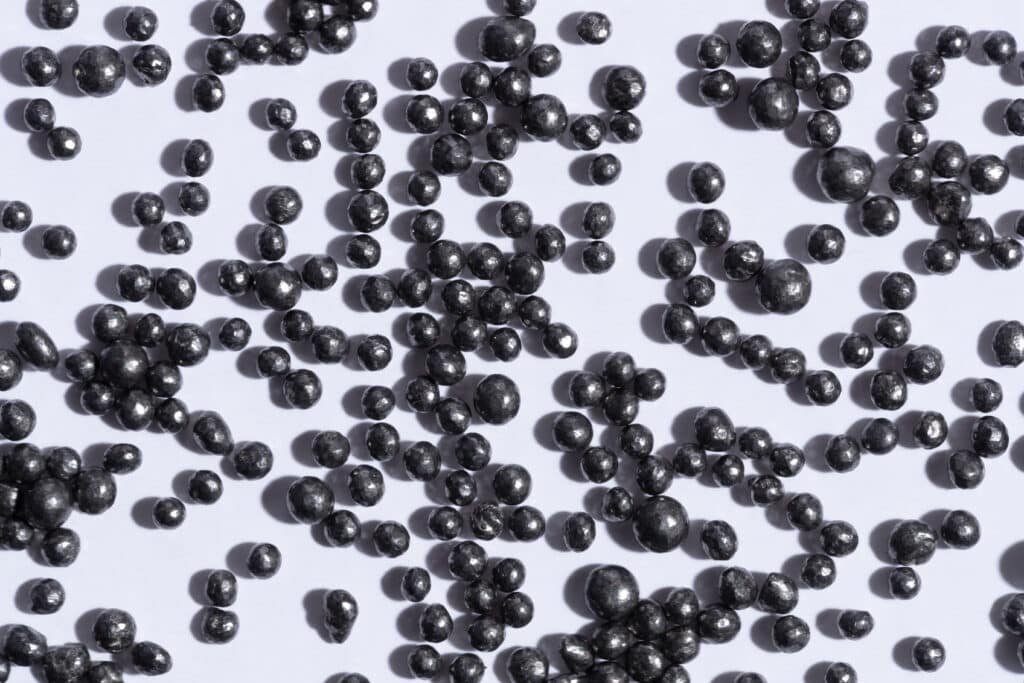

The Stelux, Winoa’s flagship product, is a metallic abrasive made of stainless steel. This composition imparts unique properties to Stelux, making it efficient in surface preparation and environmentally friendly. Stainless steel is inherently recyclable indefinitely, meaning it can be recovered, melted, and reused without compromising its properties. This feature plays a crucial role in waste reduction and resource preservation, aligning Winoa’s metallic abrasives with the fundamental principles of the circular economy.

2 Surface Preparation and Its Impact on Product Lifecycle

Surface preparation is a key step that occurs before applying paint to a piece. To maximize and ensure adhesion of the paint layer, it is essential to achieve appropriate roughness on the material. This technique allows for a significant extension of the paint’s lifespan on the piece.

Choosing the right abrasive is the foundation of this surface preparation. In the case of aluminum, Stelux is preferred for its abrasive properties and its ability to avoid ferrous contamination. The abrasive size is also carefully selected based on the desired roughness, along with the parameters of the shot blasting machine, ensuring optimal surface preparation.

3 Surface Preparation Optimization

To ensure and maintain consistent quality during surface preparation processes, monitoring and control are essential. That’s why Winoa, through WCare, dedicates services and technical experts to assist industries in optimizing their processes. The goal is to work on key parameters such as hotspot, projection speed, and operational mix, ensuring surface preparation as close as possible to the desired roughness. The benefits of WCare services also contribute to increasing industrial productivity while reducing their abrasive consumption.

4 Surface Preparation Control

In this context, precise measurement of elements is crucial. To analyze and assess the cleanliness of the shot-blasted surface, the WAClean technology was created. This measuring device reads, quantifies, and archives the cleanliness level. Other devices within the WTech program also provide precise and meaningful data to optimize surface preparation processes, such as the roughness measurement device and the dust kit to measure the dust level on the pieces.

GET TECHNICAL 2023 was an exceptional platform for engaging in fascinating roundtable discussions and highlighting the direct connection between recyclable metallic abrasives and crucial conversations about circular economy and the lifespan of product coatings.

A big thanks to Darren Bond, foreign sales manager at Eurotherm, Raia Petkova, Manager at SPPOT, and Alessia Venturi, Editor-in-Chief of IPCM (International PAINT&COATING Magazine), for inviting us and allowing us to participate in the GET TECHNICAL exhibition.

Special thanks to the Winoa teams for enlivening and being present at this event :

- Simone Rogina, Regional Sales Manager

- Matthias Merle Mounier, Specialty Products Manager

- Andrea Bevilacqua, Responsabile Vendite Divisione Industria – National Sales Manager