#BlastingOperation#CostReduction#PremiumSteelMedia

Success Story : Increase the performance of the blasting process

Increase the performance of the blasting process and reduce blasting cost in a manufacturing plant for articulated haulers

One of our famous Swedish customer manufactures articulated haulers. They previously worked with a distributor of our Spanish sister company until 2013. Now this customer is handled directly by our Swedish subsidiary which is providing them closely a regularly technical and relevant service, supported by the “Consulting and Training” W Abrasives Experts’ team.

The surface preparation process on-site was shot blasting with the Standard steel shot WS390 after welding operations and high pressure air cleaning before wet paint operations. To improve their process quality, the W Abrasives teams have identified some quality issues which were the key point of the customer requirement: this is an ongoing process accompanying them in a saving cost issue.

The results mentioned below are a mix of the constant quality issue and improvement process that allows them to increase the performance level of their blasting operations.

Then, the W Abrasives team has launched the following actions:

- On-site process audits by W Abrasives expert followed by trials in Test Center to identify the most relevant product to solve their issues.

- Introduction of Premium product Stainium SM318 in the shot blasting machine with continuous technical support of W Abrasives team. STAINIUM® is specially developed for descaling applications when little roughness is required at the end of the process. Especially available in fine grades, STAINIUM® provides a more stable operating mix.

- Custom training session for Operators, Maintenance and Management people, with a focus on the actual customer process and how to master it.

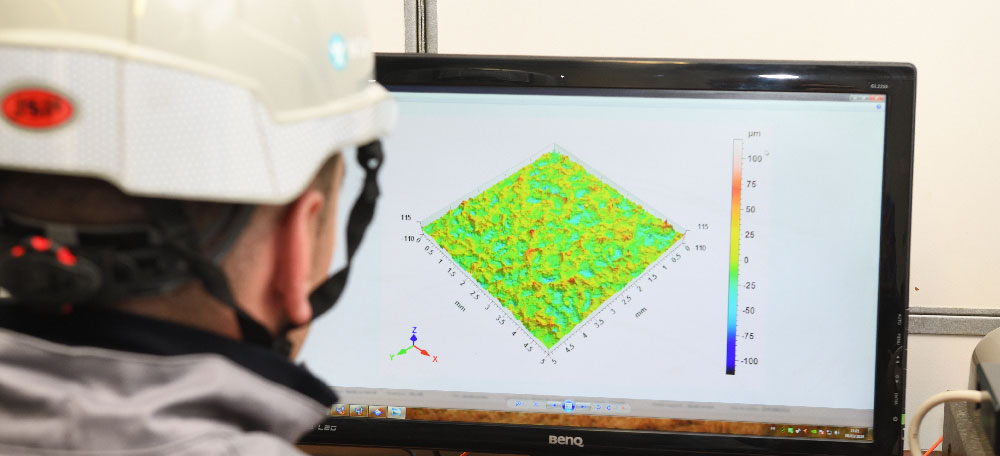

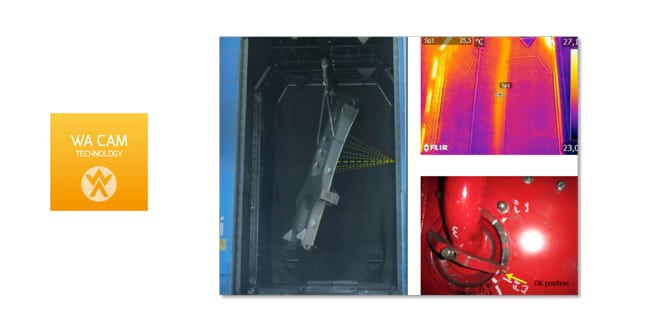

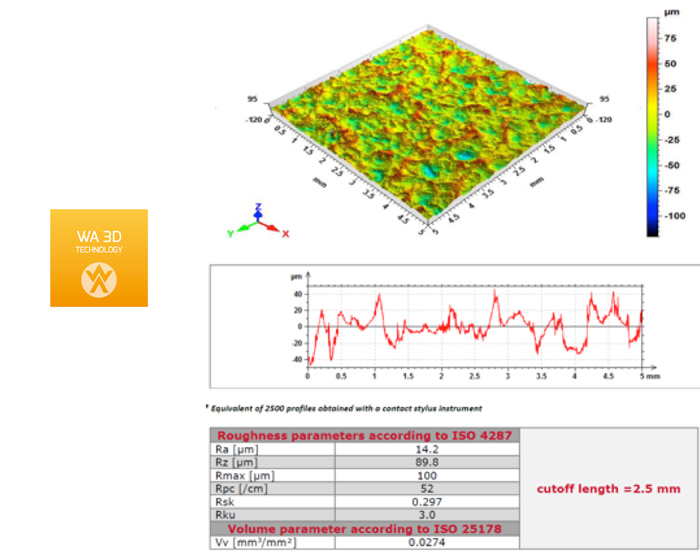

- Successful hotspot audit conducted with WA Cam and continuous use of WA 3D and dust checks to follow-up the results of the process.

As a result of this combined actions, the customer has:

- Reduced cost for maintenance: -6%

- Reduced cost for abrasive consumption: -15%

- Reduced cost due to increased direct cycle time (blasting): -15%

- Reduced cost due to increased indirect cycle time (pre-treatment): -15%

- Reduced cost due to improved quality: -42%

The saving calculations comes directly from the client and the total cost savings generated by our support is -18% or € 99.000 per year.

Thanks to the expertise of the W Abrasives team and its added value approach, WINOA is considered as a partner of choice!